Blog

October 29, 2025

A professional guide to steel grades—explaining their role in defining chemical composition, mechanical properties (e.g., ≥36 ksi yield strength), and

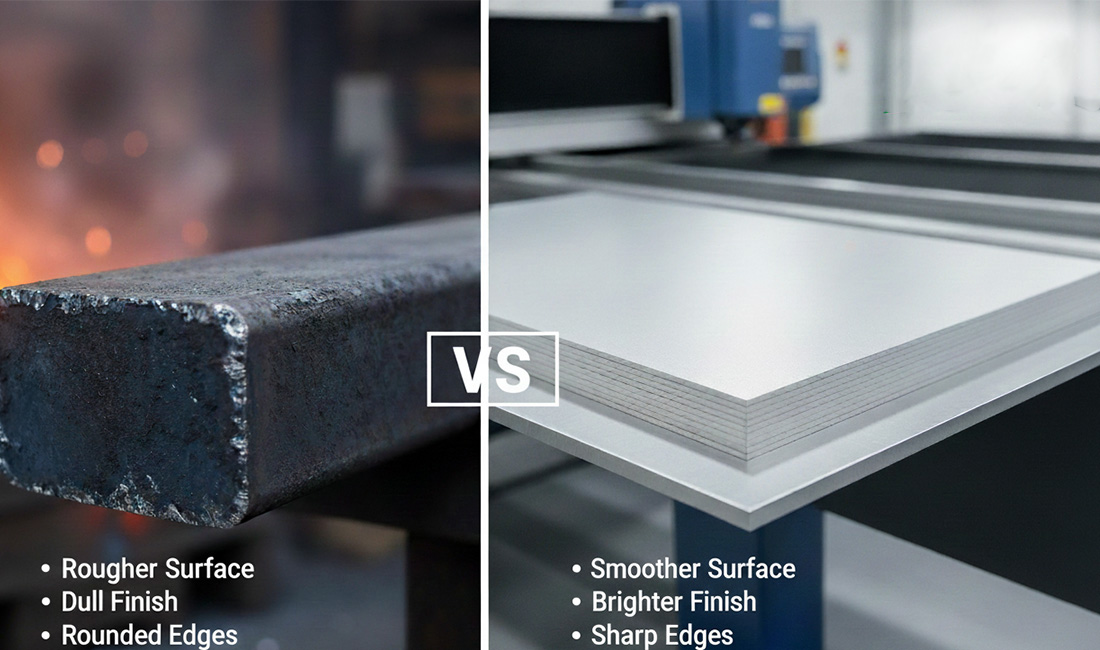

Hot Rolled vs Cold Rolled Steel: What’s the Difference?

The main difference between hot rolled and cold rolled steel is in how they are processed. The difference in processing directly affects their shape and properties.

Duplex vs. Austenitic/Ferritic Stainless Steel: Choosing the Right Shield

Three types dominate the market: duplex, austenitic, and ferritic stainless steel. Each has its own unique crystal structure, chemical makeup, and how it’s made. These differences determine their corrosion resistance, strength, and ideal uses.

Is Duplex Stainless Steel the Future? The Ultimate Guide to Duplex Steel

Duplex stainless steel is a kind of stainless steel with a special two-part structure. The combination of austenitic and ferritic crystals yields great strength, corrosion resistance, and versatility. It has become a very important material in many industries and is becoming the future of high-performance materials.

Steel Coating Methods Explained: Definition, Importance, and Methods For Performance And Corrosion Protection

Steel coating is the process of applying a thin protective layer to steel to improve resistance to corrosion, wear, and surface damage. Steel coating protects steel by creating a barrier that slows rust, extends service life, and improves performance in real working conditions. Engineers use coatings to control how steel reacts to moisture, chemicals, heat, and physical contact.

What is Aluzinc (Zn-Al-Mg) Coating?

Corrosion is steel’s persistent enemy. While standard Aluzinc has served as the industry go-to for years, the demand for superior durability has led to the rise of Zn-Al-Mg (Zinc-Aluminum-Magnesium).

Steel Casting vs. Die Casting: How to Choose the Right Metal Forming Process for Your Parts

Metal casting is a key process in modern manufacturing. It works for automotive, machinery, aerospace, construction and electronics industries.

Steel casting and die casting are two popular casting methods. They differ in important ways. These differences change part performance, production cost and how fast parts are made.

Choosing the wrong process causes problems. It can delay projects, waste money or create low-quality parts.

This article explains the key traits of both processes. It uses facts, data and real examples. It helps engineers, buyers and designers make smart choices. By the end, you will know which process fits your parts best.

-1920x1282.jpg)

Guide to High-Speed Steel (HSS): Why It’s Still a Top Choice for Cutting Tools

High-Speed Steel (HSS) is a type of tool steel known for its ability to maintain hardness and withstand high temperatures, making it ideal for cutting tools and industrial machining.

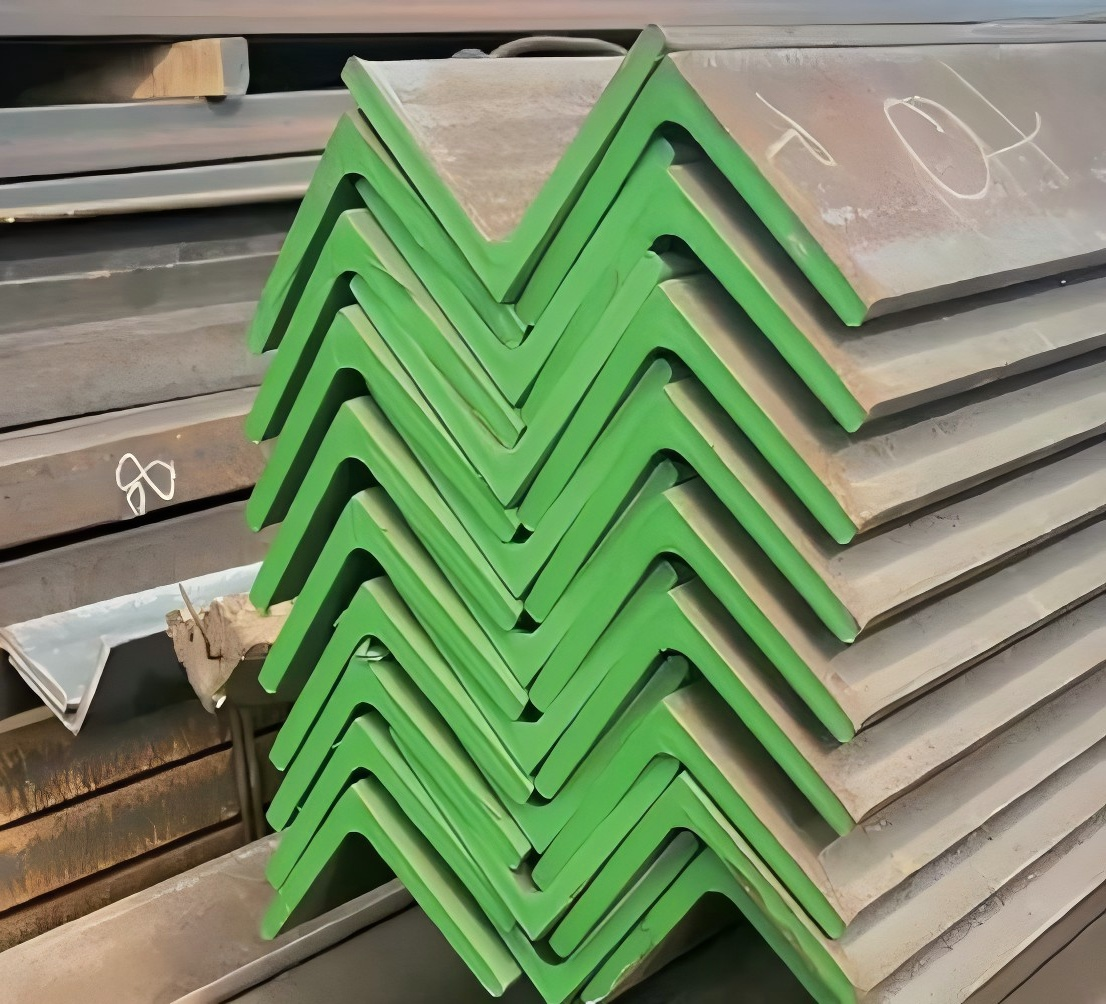

Angle Iron: The Versatile Workhorse of Fabrication and Construction

Angle iron is a piece of structural steel in the shape of an “L”, commonly used in construction and fabrication for support, framing, and reinforcement.