What is Carbon Steel? Grades, Applications & Manufacturing Processes

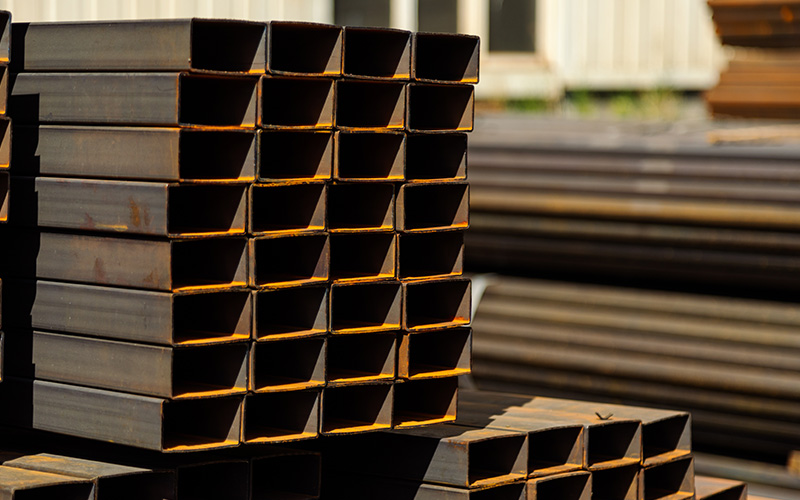

Carbon steel is a metal made mainly from iron and carbon, with small amounts of other elements. It contains up to 2.1% carbon and very low alloy content.

Because of its simple composition, durability, and cost-effectiveness, carbon steel is widely used in buildings, tools, vehicles, and cookware. When people ask what is carbon steel cookware, it refers to pans and pots made from this steel that heat evenly, last for years, and develop a natural non-stick surface over time.

Grades of Carbon Steel

Carbon steel is divided into low, medium, and high-carbon grades based on the percentage of carbon mixed with iron. The carbon level affects hardness, strength, and flexibility.

1.Low Carbon Steel (Mild Steel)

Low carbon steel contains less than 0.3% carbon. It’s soft, ductile, and easy to cut, bend, or weld. The low carbon level makes it cost-efficient and resistant to breaking. It’s commonly used in automotive panels, pipes, nails, and construction beams. Low carbon steel is ideal for forming and machining but not suitable for high-strength applications.

2.Medium Carbon Steel

Medium carbon steel contains 0.3% to 0.6% carbon. It’s stronger and harder than mild steel but still flexible enough for machining. Heat treatment improves its wear resistance and toughness. It’s widely used in gears, axles, shafts, and railway tracks, where moderate strength and durability are needed.

3.High Carbon Steel

High carbon steel contains 0.6% to 2.1% carbon. It’s extremely hard, wear-resistant, and durable but less malleable. This grade is used for knives, blades, springs, cutting tools, and high-strength wires. Because it’s brittle compared to lower grades, it often undergoes heat treatment to enhance toughness.

Applications of Carbon Steel

Carbon steel’s combination of strength, versatility, and affordability makes it essential in multiple industries.

1.Construction and Infrastructure

Low carbon steel is widely used in buildings, bridges, and pipelines because it’s easy to weld and resists deformation. It’s the backbone of modern structural engineering.

2.Automotive and Transportation

Medium and high-carbon steels are used for car frames, axles, gears, and springs. They deliver durability and resistance to wear under constant motion and load.

3.Machinery and Tools

High carbon steel is preferred for cutting tools, knives, blades, and industrial machinery. Its hardness allows precise edges and long-lasting performance.

4.Energy and Manufacturing

Carbon steel pipes carry oil, gas, and steam. It’s also used in pressure vessels and boilers for its ability to handle high heat and pressure.

5.Consumer Products and Cookware

In cookware, carbon steel is prized for its fast heating, even temperature distribution, and natural seasoning properties. What is carbon steel cookware? It’s a pan or pot made from carbon steel that combines the benefits of cast iron and stainless steel. It’s lighter than cast iron, heats faster, and becomes non-stick after repeated use. Chefs prefer it for searing meats and stir-frying because it responds quickly to heat changes.

Manufacturing Processes of Carbon Steel

The production of carbon steel involves several steps to refine iron and adjust carbon levels for different grades.

1.Smelting and Ironmaking

The process starts with iron ore, which is melted in a blast furnace with coke (a carbon source) and limestone. The result is pig iron, a material high in carbon and impurities.

2.Refining and Alloy Adjustment

Pig iron is transferred to a basic oxygen furnace (BOF) or electric arc furnace (EAF). Oxygen is blown into the molten metal to remove impurities like sulfur and phosphorus. The carbon level is reduced to the desired amount, and trace elements such as manganese or silicon are added to improve performance.

3.Casting and Forming

The molten steel is cast into billets, blooms, or slabs. These shapes are rolled or pressed into sheets, plates, or bars, depending on the intended product.

4.Heat Treatment

Carbon steel is heat-treated to achieve specific mechanical properties. The main heat treatments are:

- Annealing: Softens the steel for easier shaping.

- Quenching: Increases hardness by rapid cooling.

- Tempering: Balances hardness and ductility by reheating after quenching.

5.Finishing and Coating

After forming, the steel surface may be treated or coated to prevent rust. Common coatings include zinc galvanization, oiling, and painting.

This sequence ensures that carbon steel meets strength, flexibility, and quality standards for its final application.

Carbon steel is a versatile and dependable material made primarily from iron and carbon, with minimal alloy content. Its strength, affordability, and adaptability make it indispensable across industries—from construction and automotive to machinery and cookware. Each grade, from mild to high carbon steel, offers unique advantages in forming, cutting, or resisting wear.

In cookware, carbon steel combines the best qualities of cast iron and stainless steel—it heats evenly, lasts for years, and develops a natural non-stick surface with use. Whether forming the frame of a bridge or the base of a chef’s pan, carbon steel remains a timeless material that delivers performance, durability, and value.

Learn More About Our Products?

Contact Now