Integrated wall panels are a new type of interior decoration material that has emerged in recent years. Essentially, they are synthetic (composite) materials that integrate the characteristics (advantages) of various materials. Due to their unparalleled advantages over single materials and moderate prices for certain types, they have been quickly recognized by customers and gradually formed a distinct category of decorative materials.

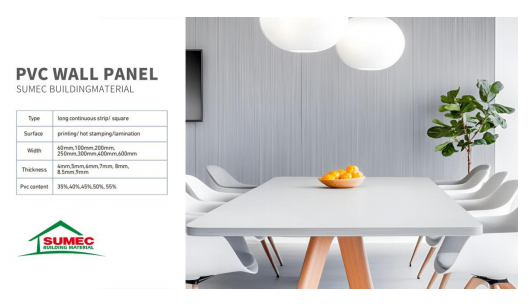

Among the common integrated wall panels on the market, a major category is polyvinyl chloride-resin based. PVC is the abbreviation of polyvinyl chloride, a polymer formed by the free radical polymerization of vinyl chloride monomers under initiators such as peroxides or azo compounds, or under the action of light and heat. Simply put, it is a type of plastic. In its unprocessed state, PVC is an amorphous white powder. Polyvinyl chloride wall panels, commonly known as PVC wall panels, are boards made from polyvinyl chloride resin and are widely used in architectural decoration and industrial fields. They are produced through an extrusion molding process, with common types including bamboo-fiber boards, stone-plastic wall panels, wood-plastic boards, plastic-steel boards, and pure plastic boards (gradually being phased out). Due to differences in formulations, processes, and quality grades, prices vary significantly.

PVC wall panels can be used in various scenarios. For example, they are suitable for living room feature walls, bedroom walls, kitchen walls, and especially for scenarios where the wall base is uneven or requires quick renovation. They can also be used for exterior walls of low-rise buildings, balcony railings, and air conditioner outdoor unit enclosures, serving both decorative and protective purposes for walls. In offices, shops, restaurants, gyms, and other spaces, different patterns and colors can be matched to enhance the visual appeal of the space while reducing decoration costs. In places with high requirements for fire resistance, moisture resistance, and easy cleaning, such as hospitals, schools, and nursing homes, PVC wall panels offer stain resistance and easy scrubbing. They can also be used in spaces requiring sound insulation, such as home theaters and conference rooms. Additionally, they can be combined with thermal insulation materials to produce PVC insulated wall panels, which help improve a building’s thermal insulation performance and reduce air conditioning energy consumption.

A common question is: Does PVC board contain formaldehyde? Formaldehyde may remain and be released into the air if additives used in the production of PVC boards-especially blowing agents and stabilizers-do not fully react. There are many types of PVC boards, such as soft PVC boards, rigid PVC boards, PVC skin foaming boards (PVC skin foaming boards), and PVC free foaming boards (PVC free foaming boards). Among these, soft PVC boards, skin foaming boards, and free foaming boards require large amounts of softeners or blowing agents, which can lead to higher formaldehyde content in the boards. Therefore, if PVC wall panels are used in interior decoration, it is essential to know methods for removing formaldehyde to ensure health and safety. If you are concerned that purchased PVC boards contain formaldehyde, the simplest method is ventilation: open indoor doors and windows to allow the installed PVC boards to ventilate thoroughly. Maintaining this for 2-3 months can ensure no harm to the human body. If you purchase PVC foaming boards, it is best to place them in a ventilated area for at least 3 months before installation.

As a widely used building material, PVC wall panels have continuously evolved in recent years. Particularly, the increasing emphasis on environmental protection has influenced the product iteration of PVC wall panels. Thus, we can observe that PVC wall panels are developing toward greenization, functionality, and high-endization. For example, bio-based PVC has emerged, which uses plant-based raw materials to replace part of petroleum-based raw materials. Some products are designed to be recyclable, effectively reducing carbon emissions. Other products use processes such as 3D printing and high-definition film lamination to create more diverse and realistic surface textures.