Annual 20+ Million Tons Supplying Across 120+ Countries

SUMEC Metal Group Since 1978Top 3 Steel Exporter in China

SUMEC Metal is a steel supplier and integrated supply chain service provider,

offering steel solutions for various shapes, crafts, alloys with one-stop services,

listed on Shanghai Stock Exchange. (SHA:600710)

Stable Supply From 100+ Top Mills Globally

Backed By 40 Years of Industry Experience

Flexible Payment Options

Steel Products

Explore MoreFrom semi-finished steel to precision-engineered coated and cold rolled coils, our steel solutions support manufacturing, construction, infrastructure, and industrial applications worldwide.

Our semi-finished steel products, including billets, blooms, and slabs, serve as the foundational raw materials for downstream steel manufacturing. Produced

Cold-rolled steel is made by processing hot-rolled steel at room temperature, prized for its superior surface finish, tight tolerances, and

Hot-rolled steel is the essential foundational material of modern manufacturing and construction, valued for its inherent strength, excellent formability, and

Coated/Plated Steel is a high-performance material for corrosion-prone scenarios, valued for its strong rust resistance, enhanced aesthetics, and long service

Why Choose SUMEC Metal?

About us

SUMEC Metal is one of the largest state-owned steel suppliers in China established

in 1978 (SHA:600710). As a global leading steel supplier, we offer a wide range of steel products and one-stop steel supply chain services and solutions, integrating transport

and logistics, market information, technical support, financing support and sales.

3+ Million

Annual Exporting Volume

100+

Cooperating Mills

5000+

Global Customers

120+

Countries

Steel Shapes

At SUMEC Metal, you can find all shapes of steel for your special demands, such as H-beam shape steel, C-shape steel, and plates with checkered patterns, etc

Steel Coils

Flat coil, slit coil,

oscillated Coil, etc

Steel Plates

Checkered patterns

available on the surface

Steel Bars

Flat Bars, Round Bars,

Square Bars, etc.

Channel Shape

C channel, U Channel, MC

Channel, etc.

H-Beam Shape

Structural Steel Beam Made

from Rolled Steel

Steel Angles

L-shape, two materials

meet at a right angle

Steel Wires

Rectangular, round,

gexagonal or square shape

Global Project Cases

See our large-scale international projects including supplying the landmark cross-sea,infrastructure project in Southern Europe, and an industrial sugar factory supply case in Asia.

SUMEC METAL FORGING TRUST

Source From Global Metal Supply Chain

Every Partner Is Our VIP Client. Get your ideal one-stop steel supply chain services with integrating logistics, market information, financing support, technical support, procurement and sales.

Get SUMEC Metal Market Newsletter

By clicking Register, you acknowledge that you have read and accepted our Terms and Conditions.

Knowledge Base of Steel Manufacturing

As a leading global steel supplier, SUMEC Metal shares valuable insights on semi-finished steel, industry trends, production processes,and best practices. Our blog is designed to empower customers and partners with up-to-date steel knowledge.

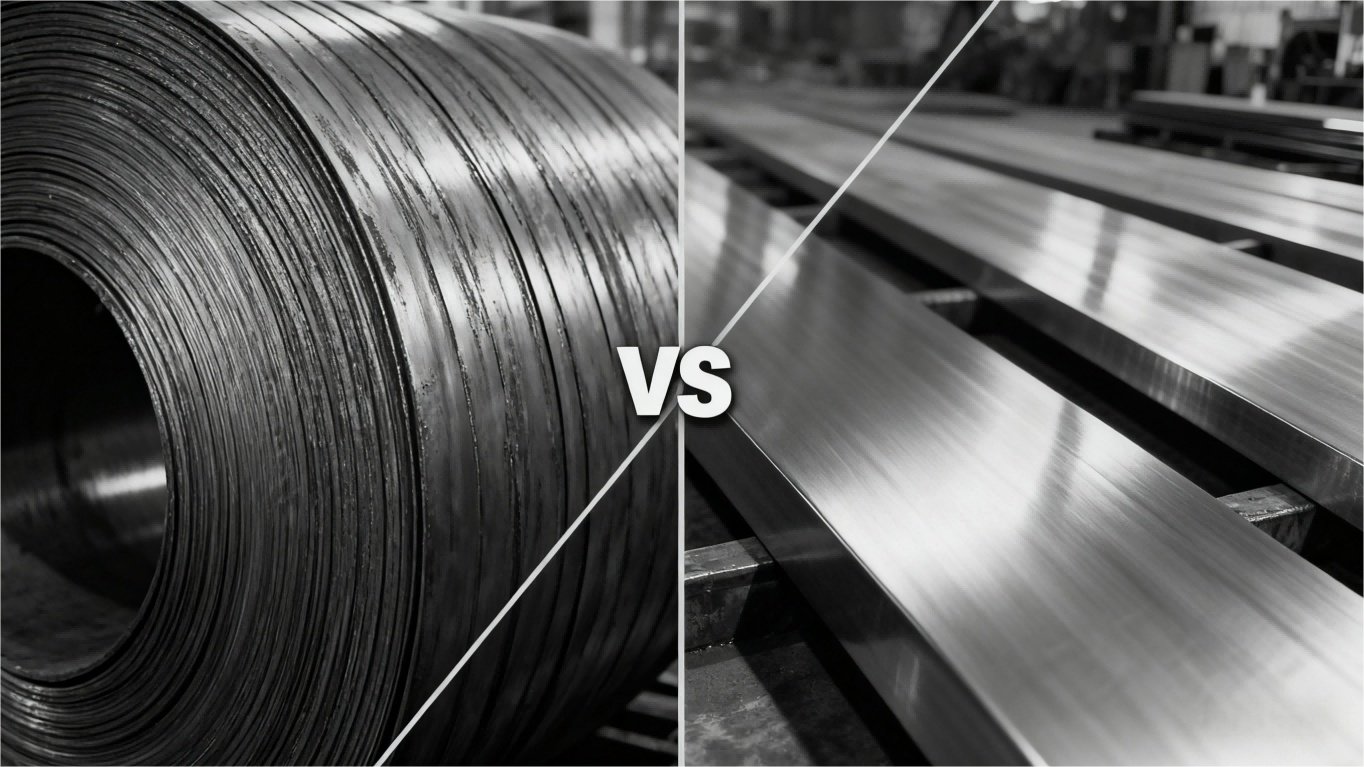

September 16, 2025

Hot Rolled Steel vs Cold Rolled Steel: Differences & Selection GuideRolled steel is a type of steel that has been processed through a series of rollers to change its shape,Veiw Details

September 15, 2025

Hot Rolled vs Cold Rolled Steel: What’s the Difference?Rolled steel is a type of steel that has been processed through a series of rollers to change its shape,Veiw Details