Duplex vs. Austenitic/Ferritic Stainless Steel: Choosing the Right Shield

Stainless steel is more than just a corrosion-resistant alloy—it’s a staple in our daily lives and big industries alike. You’ll find it in aerospace components, ships, chemical plants, and even the buildings around you, quietly standing up to wear and tear.

Three types dominate the market: duplex, austenitic, and ferritic 스테인리스 스틸. Each has its own unique crystal structure, chemical makeup, and how it’s made. These differences determine their corrosion resistance, strength, and ideal uses.

This article breaks down what makes each of these three stand out. No fancy jargon, just real-world examples to help you pick the right one for whatever project you’re tackling, big or small.

What Are Duplex, Austenitic, and Ferritic Stainless Steel?

1. Duplex Stainless Steel

Duplex stainless steel gets its name from a simple fact: its internal structure is split almost evenly—50% austenite, 50% ferrite. That dual makeup isn’t just a quirk; it’s what gives the material its unique strengths.

It’s packed with high levels of chromium (20–28%), molybdenum (1–5%), and a touch of nitrogen (0.1–0.3%). Together, these elements act like a team, boosting both its ability to fight corrosion and its overall sturdiness.

You won’t find a clear “yield point” here—this steel is all about brute strength and flexibility. It holds up under tension exceptionally well and stays tough, even when submerged in seawater or exposed to harsh acids. “Duplex stainless steel bridges the gap between strength and corrosion resistance, making it irreplaceable in harsh marine environments.”

2. Austenitic Stainless Steel

Austenitic stainless steel is non-magnetic and has a uniform austenitic structure at room temperature, which is a quick way to spot it.

Chromium (16–26%) and nickel (8–22%) are its main ingredients. Nickel is the unsung hero here; it keeps that austenite structure stable, so the steel maintains its properties no matter how you shape it.

It’s incredibly easy to work with—bend it, stamp it, weld it, or form it into pipes, tanks, even your kitchen pots and pans. 304 is the most common grade, while 316 offers superior corrosion resistance for harsher mild environments.

3. Ferritic Stainless Steel

Ferritic stainless steel is magnetic, high in chromium (10.5–30%), and contains little to no nickel. That lack of nickel shapes both its strengths and its price tag.

It holds up well against general corrosion and high temperatures. Best of all, it’s the most budget-friendly option among the three, making it a go-to for cost-conscious projects.

It’s not perfect, though. It lacks toughness at room temperature and is tricky to weld—heat can make it brittle afterward. 430 and 409 are the grades you’ll most likely encounter in daily use.

Key Differences Between Duplex, Austenitic, and Ferritic Stainless Steel

Microstructure, mechanical strength, corrosion resistance, cost—these four factors set the three types apart. They’re the reason one works great in a chemical plant and another is better for your fridge door.

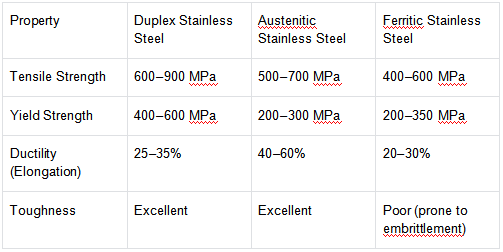

1. Mechanical Properties

Duplex 스테인리스 스틸 has the highest yield strength—roughly twice that of austenitic steel. If you’re building something that needs to hold heavy loads, this is your material.

Austenitic steel, though, is the most flexible. It bends and shapes without breaking, making it perfect for parts that need intricate forms.

Ferritic steel has decent strength but falters in cold temperatures. It gets brittle fast when it’s icy, so skip it for outdoor projects in cold climates.

2. Corrosion Resistance

Duplex steel excels in tough, corrosive environments, resisting pitting and crevices even when soaked in seawater or acids—why it’s a favorite for marine and chemical work.

Austenitic steel’s performance varies by grade. 304 handles everyday environments, while 316, thanks to added molybdenum, stands up to saltwater. “316 stainless steel is the gold standard for food processing and coastal applications due to its balanced corrosion resistance.”

Ferritic steel resists general rust well enough but can’t handle high-chloride areas, so stick to dry indoor spaces for this one.

3. Cost

Ferritic steel is the budget winner. No nickel means lower raw material costs—usually 20–30% cheaper than austenitic steel.

Austenitic steel sits in the middle. Its price hinges on nickel prices, with 316 costing 10–20% more than 304 because of its extra molybdenum.

Duplex steel is the priciest. Making it requires precise control over its chemical mix and heat treatment—adding up to 30–50% more cost than 316.

4. Weldability

Austenitic steel has the best weldability—use common methods like TIG or MIG, and it won’t get brittle afterward, no extra steps needed.

Duplex steel can be welded, but you have to watch the heat. Too much, and you’ll mess up its dual structure, weakening its corrosion resistance.

Ferritic steel is tricky to weld. Heat makes its structure coarse and brittle, so post-weld heat treatment is usually necessary.

How to Choose Between Duplex, Austenitic, and Ferritic Stainless Steel?

Picking the right stainless steel means matching it to your project’s needs—environment, strength requirements, and budget.

1. Consider the Service Environment

Harsh spots—seawater, acids, salty air? Go with duplex steel. It stays strong for years, no rust or small pits to worry about.

Mild environments—indoor spaces, freshwater, food prep areas? Go with austenitic steel (304 or 316). It hits that sweet spot between performance and cost.

Dry indoor areas—decorations, home appliances? Go with ferritic steel (430). It’s cheap and resists rust just enough for daily use.

2. Consider Mechanical Performance Requirements

Parts holding heavy loads? Duplex steel is your best bet. It’s tough and strong, built to last under stress.

Complex shapes? Austenitic steel bends and forms easily, no cracks or breaks.Light decorations—door handles, trim? Ferritic steel saves money without sacrificing basic function.

3. Consider Welding and Fabrication Needs

Lots of welding? Austenitic steel keeps things simple. Weld it, and it stays stable afterward.

Little to no welding—stamped parts, small components? Either duplex or ferritic steel works fine. No need to overcomplicate things.

4. Consider Budget Constraints

Tight budget, basic rust resistance? Ferritic steel is the way to go.

Balanced budget, good performance? Austenitic steel (304 or 316) gives you the most value.

High budget, harsh conditions? Duplex steel is worth the investment. It lasts longer and avoids costly replacements down the line.

Typical Application Scenarios

1. Duplex 스테인리스 스틸 애플리케이션

Duplex steel is for jobs that demand both strength and corrosion resistance:

- Marine engineering: Ship hulls, offshore platform parts, seawater pipes that handle constant salt exposure.

- Chemical industry: Pressure vessels, heat exchangers, and pipes that carry acidic fluids.

- Oil and gas industry: Wellhead equipment and pipelines for corrosive fuels.

2. Austenitic 스테인리스 스틸 애플리케이션

Austenitic steel is the most versatile, popping up in almost every industry:

- Food and beverage industry: 304 grade for kitchen utensils, food processors, and storage tanks that need easy cleaning.

- Medical industry: 316 grade for surgical tools and hospital furniture—hygienic and rust-resistant.

- Construction industry: Curtain walls, handrails, and decorative parts that look good and last.

3. Ferritic Stainless Steel Applications

Ferritic steel is for low-cost, low-corrosion jobs:

- Automotive industry: Exhaust systems, trim parts, and fuel tanks that handle heat but not harsh chemicals.

- Household appliances: Refrigerator panels, washing machine drums, and oven liners—affordable and durable.

- Architectural decoration: Indoor handrails and door handles that don’t face weathering.

자주 묻는 질문

1. Is duplex stainless steel magnetic?

It is. That 50% ferrite content makes it magnetic—just not as strong as ferritic steel. Austenitic steel, by contrast, isn’t magnetic at all.

2. Which is more corrosion-resistant: 316 stainless steel or duplex stainless steel?

Duplex steel wins here. It handles higher salt concentrations than 316, making it better for seawater or acidic environments.

3. Can ferritic stainless steel be used outdoors?

Only in dry climates. Humidity or coastal air will make it rust. If you do use it outdoors, add a protective coating to keep it in good shape.

4. Why is austenitic stainless steel so widely used?

Austenitic stainless steel’s widespread use comes from its balanced performance—flexibility, weldability, rust resistance, and cost. “It’s not the best at one thing, but it’s reliably good at almost everything.”

제품에 대해 자세히 알아보시겠습니까?

지금 문의