Angle Iron: The Versatile Workhorse of Fabrication and Construction

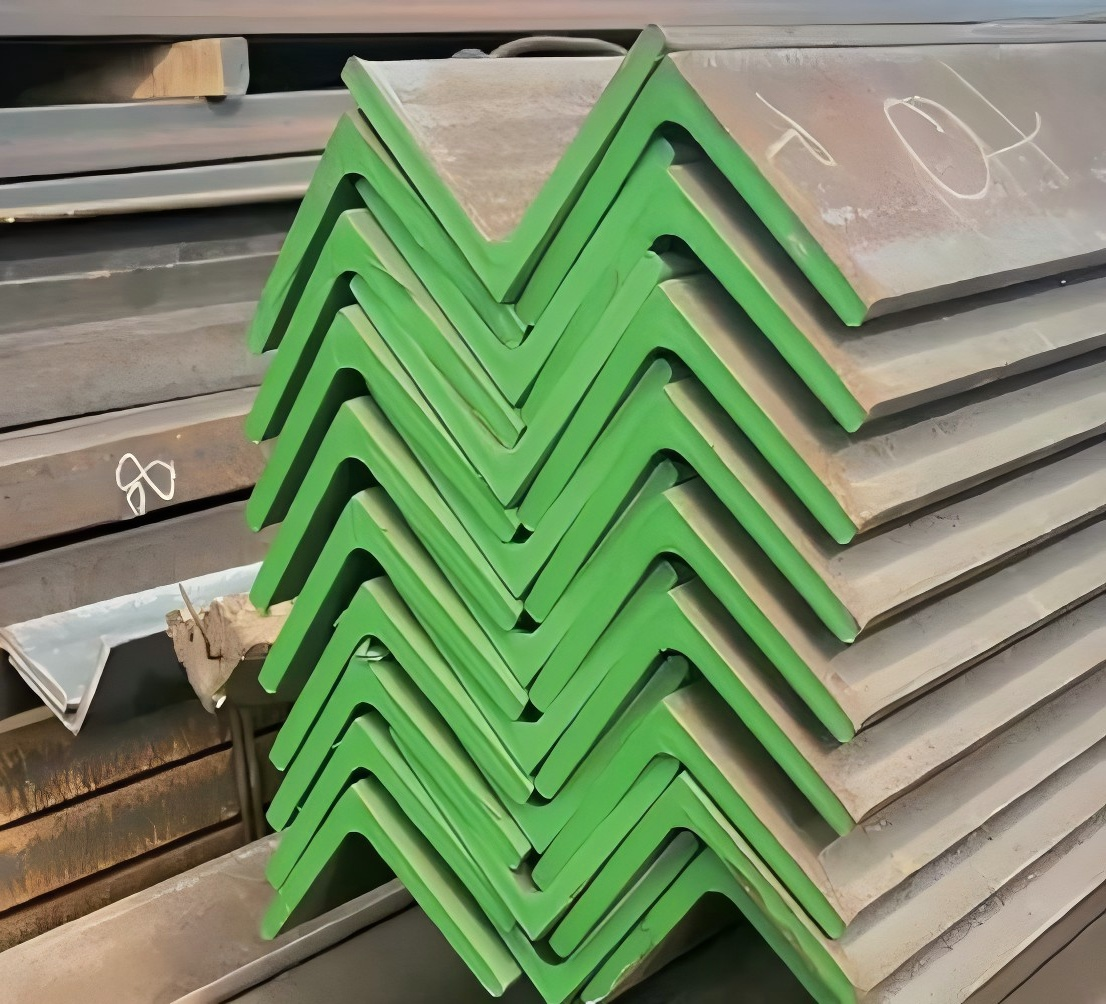

Angle iron is a piece of structural steel in the shape of an “L”, commonly used in construction and fabrication for support, framing, and reinforcement. It has been a trusted structural component for years. With its simple design and reliable performance, angle iron is a foundational element in countless projects across various industries.

Angle iron is popular for three fundamental strengths: strength, ease of production, and low cost. From building frames to braces and industrial frameworks, angle iron has a wide range of uses. It is suitable for both small manufacturing projects and large construction projects.

This blog will explain what angle iron is, its types, key benefits, and top applications. It also shares how to pick the right one for your project.

Whether you’re an engineer or contractor, this guide will break down the essentials of this versatile workhorse.

1. What Is Angle Iron?

Angle iron is a metal component with an L-shaped cross-section. It forms a 90-degree angle between two flat legs—either equal in length or unequal, depending on the use. The simple, functional design makes it widely used in construction, manufacturing, and transportation.

The L-shape of angle iron gives it natural resistance to bending, twisting, and shape change when forces are applied. This makes it a cost-effective solution for structural and industrial needs. It is commonly used to build house frames, supports, braces, and other framework components.

Most angle iron is made from hot-rolled mild steel, but it is also available in stainless steel and aluminum. It follows strict industry standards. These include:

- ASTM (American Society for Testing and Materials) A6/A6M for dimensions

- ASTM A36 for mild steel strength

- AISC (American Institute of Steel Construction) guidelines for structural use

2. Types of Angle Iron

Angle iron has different types to meet different structural requirements. It is classified based on three factors: material, leg design, and manufacturing process.

자료별

- Mild steel (low-carbon steel): Mild steel is the most common material for angle iron, accounting for over 90% of the total amount. It is popular for the balance of strength, ductility, and cost-effectiveness. It can offer high strength and is easy to cut, weld, and drill. It is also cost-effective for large-scale projects. Mild steel angle iron is ideal for most structural applications, from indoor structural supports to building frames, machinery bases, etc.

- Stainless steel: Stainless angle iron is a premium material option known for its superior corrosion resistance, durability, and aesthetic appeal. It contains chromium and nickel element, which can form a protective layer on the surface, preventing rust and damage. Stainless steel angle iron is widely used in outdoor projects or in humid environments (e.g., marine vessels, food-processing plants).

- Aluminium: Angles made from aluminium are light but rigid. It is perfect for projects where weight is critical and not losing structural integrity. It is lightweight and corrosion-resistant, and easy to process. It is the best choice for light-load applications, including aerospace components, portable equipment frames, etc.

By Leg Design

- Equal angle iron: The angle iron with two legs of the same length (e.g., 2×2 inches, 3×3 inches, or 4×4 inches). Equal angles are used in general building structures, frame supports, or simple reinforcements that require enhanced balance.

- Unequal angle iron: The angle iron with different lengths of legs (e.g., 3×2 inches, 6×3 inches). Unequal angle iron is used for projects that need stronger support on one side, including fixing panels to walls or strengthening uneven structures.

By Manufacturing Process

- Hot-rolled: Angle iron that is made by heating and forming under pressure. Hot-rolled angle is cost-effective and durable. It is the most common type for construction and manufacturing.

- Cold-rolled: Angles that are shaped at room temperature and have a smoother surface, and more exact sizes. It is used for projects that need a polished finish or precise fit (e.g., furniture frames, decorative structural components).

3. Key Characteristics & Benefits

Angle iron stands out as a top structural choice thanks to its core characteristics and practical benefits. These traits make it reliable, adaptable, and cost-effective for fabrication and construction projects.

Core Characteristics

- Strength & Rigidity: Its L-shaped cross-section delivers exceptional structural integrity, resistance to bending, and load-bearing capacity. Most mild steel angle iron meets ASTM A36 standards, with tensile strengths ranging from 400 MPa to 600 MPa. Its strength-to-weight ratio is impressive—it carries heavy loads without adding excess weight to structures.

- Durability & Corrosion Resistance: It is built to withstand wear, stress, and environmental factors. Stainless steel variants offer maximum rust and chemical resistance, while galvanized mild steel (coated with zinc) provides reliable protection against moisture. Even uncoated mild steel maintains long service life in indoor or low-humidity settings.

- Fabrication Versatility: It is easy to cut, drill, weld, and bolt. This flexibility allows for custom shapes, quick assembly, and secure connections.

Key Benefits

- Cost-Effectiveness: It is cheaper than I-beams, channels, and webs. Over 90% of angle iron is made from low-carbon steel, one of the most common and affordable metals. The production cost is also low as it is easy to produce, with little waste, and has a mass production effect. This makes it ideal for large projects and tight budgets.

- High Strength-to-Weight Ratio: It carries large loads but weighs little. The L-shape structure distributes forces and can resist bending and torsion. The steel and aluminum used is naturally strong and lightweight than other materials like concrete. This makes structures lighter without losing strength.

- Great Versatility: It works for many uses. The L-shape fits both horizontal and vertical layouts, and is easy to cut and weld. It is widely used in projects that require simple framing, intricate designs, and brackets.

- Sustainability: It is an eco-friendly choice. Steel and aluminum angle iron are 100% recyclable. They have a long lifespan and can be reused. This cuts waste, fitting sustainable construction practices.

-1-1920x1281.jpg)

Image Source:699pic.com

4. Applications in Fabrication & Construction

Angle iron is widely used in fabrication and construction because of its strength, versatility, and low cost. Here are some of its most common applications:

Fabrication Applications

- Machinery & Equipment Framing

Angle iron can be used as a strong frame for industrial machinery and assembly platforms. It can carry heavy loads without deforming, ensuring equipment stays stable even under repeated use.

- Industrial Containers & Conveyors

These L-shaped metal pieces are tough, wear-resistant, and reliable. As a result, they are used to make industrial containers and conveyor systems. They can hold up to heavy use, avoid damage, and stay functional for many years.

- Automotive Components

Angle iron can also be used to form trailer frames, vehicle chassis, and mounting brackets. It is lightweight, strong, and cost-effective, and can add strength without extra weight. Products made with angle iron remain stable, safe, and fuel-efficient.

- Warehouse Racking

It makes vertical and horizontal supports for warehouse shelving. Its tensile strength holds stacked pallets, boxes, and equipment, keeping storage systems secure.

- Custom Fabrications

It is easy to cut, weld, and shape, making it suitable for custom workbenches and tool racks in workshops. It can quickly adapt to unique design requirements.

Construction Application

- Building & Bridge Frameworks

Angle iron is the core framework for warehouses, buildings, and bridges. Its L-shape resists bending and can support heavy structural loads effectively.

- Concrete Reinforcement

In reinforced concrete beams and columns, the angle iron can boost their strength and stability. It can also prevent beams and columns from cracking, and makes the building last longer.

- Trusses & Braces

Used for trusses, wall braces, and structural supports. It can handle pushing and pulling forces, keep buildings rigid, safe, and stable against wind and movement.

- Outdoor Structures

Galvanized or stainless steel angle iron can be used to build fences, canopies, and decks. It is rust-proof, weather-resistant, and long-lasting. It can withstand the erosion of rain, salt spray, and intense sunlight without rusting.

- HVAC & Infrastructure Support

It holds up HVAC units and ducts, carrying their weight. Meanwhile, it requires little maintenance and cost, and is highly reliable. It can also secure cable trays and electrical supports, keeping the telecommunication lines safe, neat, and intact.

-1920x1280.jpg)

Image Source:699pic.com

5. How to Choose the Right Angle Iron for Your Project

To choose the right angle iron for your project, you should match it to the specific project requirements. Here are five factors that you need to think about before making a decision:

① Consider the load requirements

The first thing to consider is the load requirement.

If your structure only bears steady or static loads, such as shelving, framing, or partitions, a standard mild steel angle is strong enough.

But if your project involves dynamic or vibrating loads—for example, machinery bases, trailers, or platforms that move—choose thicker angles or higher-grade steel.

Dynamic loads put repetitive stress on the material, and thicker or stronger steel prevents bending or fatigue failure.

② Think about the environment

Second, think about the operating environment. The environment determines corrosion resistance needs.

For dry environments or certain indoor projects, such as workbenches or indoor framing, low-cost standard mild steel is sufficient.

For outdoor, coastal, or humid areas, stainless steel or galvanized angle iron is a better choice to prevent rust.

③ Check dimensions and shape

Next, confirm the adaptability of dimensions and shape. Choose the right shape of angle iron and measure the size for your layout.

Equal angle iron is good for balanced load support, like shelf frames.

Unequal angle iron fits uneven structures, where you need more support in one direction, for instance, wall panels.

④ Take fabrication into account

Besides, don’t forget to take fabrication needs into account.

If you need to weld, cut, or drill the angle iron, mild steel angle iron is the best choice, as it’s easy to process with ordinary tools.

For projects that require special corrosion resistance, like coastal fences, medical equipment support structures, stainless steel iron works better.

Aluminium angle iron works for light-load projects, especially in aerospace components, portable equipment frames etc.

⑤ Refer to the industry standard

Last but not least, check the related industry standard when purchasing angle iron products. For the critical dimensional parameters of angle steel, industry standards such as ASTM A6/A6M, ASTM A36, and AISC guidelines have provided benchmark measurements.

Confirm your supplier can provide relevant certification to verify the products meet these standards, which means they are safe, of good quality, and compatible with other parts.

제품에 대해 자세히 알아보시겠습니까?

지금 문의