The Low-Carbon Transformation Path of Steel Channels

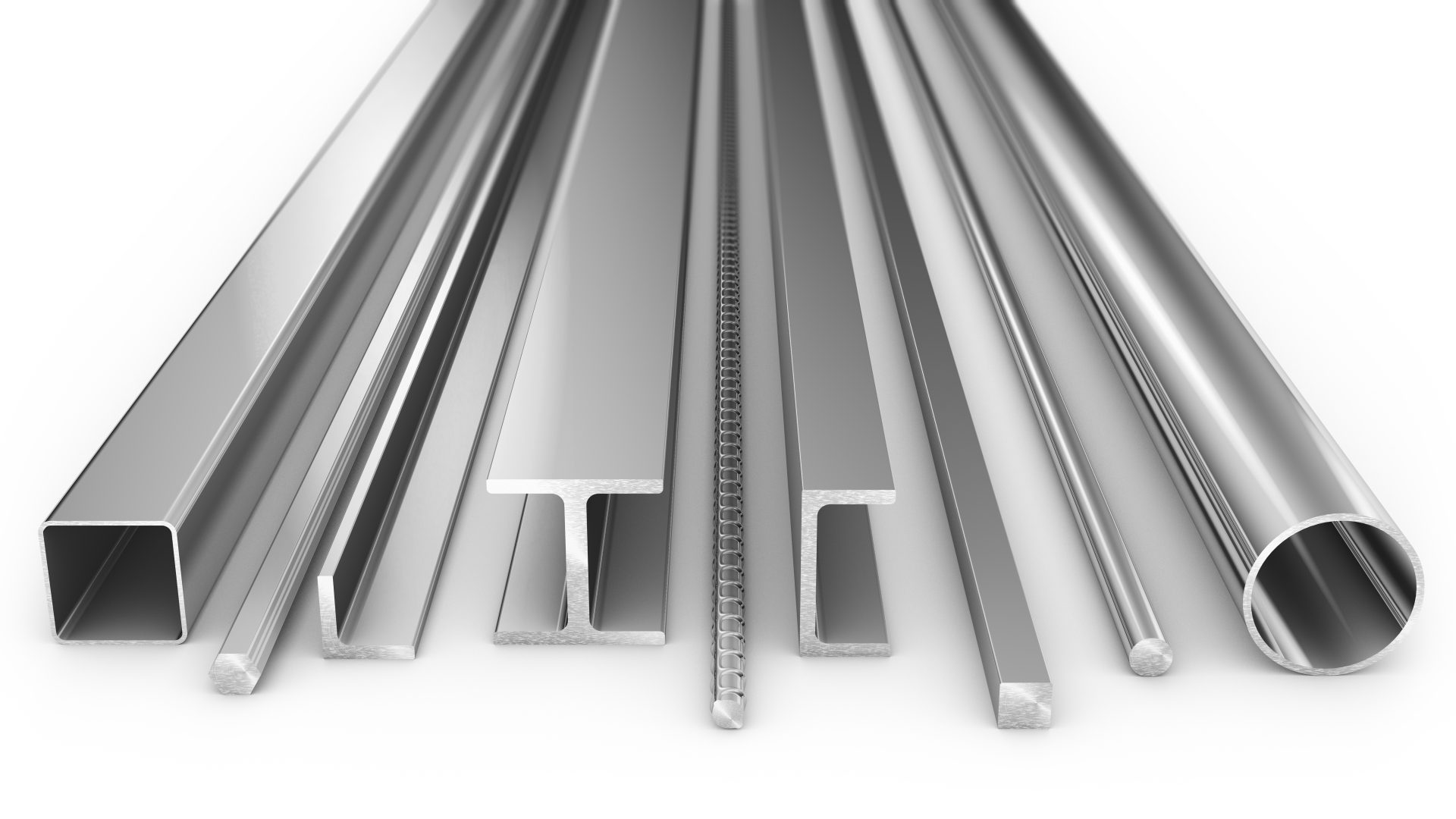

In the framework of steel structures, steel channels, with their unique U-shaped cross-section, serve as the core load-bearing component. Amidst the global steel industry’s shift towards low-carbon development, this fundamental steel material, due to the rigid demands of its applications, has become a crucial link between traditional manufacturing and green development. Since 2025, the complex changes in the global steel market and breakthroughs in green production technologies have jointly reshaped the development landscape of the steel channel industry.

The value of steel channels has long permeated the capillaries of industry and infrastructure. As a long strip of steel with a U-shaped cross-section, it plays a crucial role as purlins and wall beams in steel structure buildings due to its excellent bending and torsional resistance; it is used as equipment supports and guide rails in machinery manufacturing; and it forms the support system for shelving in logistics and warehousing. The regional differentiation of global infrastructure investment in 2025 directly impacts the demand landscape for steel channels—while the Asian market is dragged down by low steel prices, the Southeast Asian infrastructure boom is driving steady growth in demand for low- to mid-range steel channels; the European and American markets, due to upgraded green building standards, are seeing a continued increase in their willingness to purchase high-strength, low-emission steel channels.

A green production revolution is injecting new momentum into the steel channel industry. Traditional steel channel production relies on blast furnace processes, resulting in high carbon emissions. However, the STEGRA project in Sweden, the world’s first large-scale green steel plant, provides a feasible path for the decarbonization of steel channels. This factory utilizes a 690 MW electrolyzer to produce green hydrogen using renewable energy, replacing coal as a reducing agent. The resulting sponge iron has a 95% lower carbon footprint than traditional blast furnaces. After being smelted into steel in an electric arc furnace, it is processed into steel channels, completely altering the product’s carbon footprint. While this green steel channel is slightly more expensive, it has become a preferred choice for high-end construction projects in Europe and the US, given the impending implementation of the EU’s Carbon Border Adjustment Mechanism (CBAM). Orders for this product are expected to increase by over 30% year-on-year in the second half of 2025.Looking to the future, the development of the steel channel industry will revolve around both “carbon reduction” and “quality improvement.” Meanwhile, adjustments in trade patterns are driving companies to accelerate regional expansion, circumventing tariff barriers by establishing factories overseas. As the “basic backbone” of industry and infrastructure, steel channels are transforming from simple structural components into witnesses to the green transformation of the steel industry and the restructuring of global trade, supporting global construction while writing a new chapter in low-carbon development.