Steel Casting vs. Die Casting: How to Choose the Right Metal Forming Process for Your Parts

Table of Contents

- Introduction: What Role Do Steel Casting and Die Casting Play in Manufacturing?

- What Are the Basic Definitions and Core Principles of Steel Casting vs. Die Casting?

- Steel Casting

- Die Casting

- How Do Steel Casting and Die Casting Differ in Core Aspects?

- Which Metals Work for Steel Casting vs. Die Casting?

- Which Process Suits Small-Batch vs. Mass Production?

- Part Precision & Surface Quality: How Do Steel Casting and Die Casting Compare?

- Which Process Handles Complex vs. Regular Shapes?

- Which Process Offers Better Value for Initial Investment vs. Mass Production?

- Which Process Delivers Toughness vs. Strength?

- What Are the Typical Application Scenarios for Steel Casting and Die Casting?

- What Types of Industrial Components Benefit from Steel Casting?

- What Types of Industrial Components Benefit from Die Casting?

- How to Select Between Steel Casting and Die Casting: A Decision Framework

- Step 1: Clarify Core Requirements – What Material, Batch Size and Precision Do You Need?

- Step 2: Analyze Part Characteristics – What Size, Structure and Mechanical Properties Are Required?

- Step 3: Evaluate Cost & Production Cycle – What Budget and Timeline Do You Have?

- Step 4: Reference Practical Cases – What Do Real-World Applications Show?

- What Are Common Misconceptions and Precautions for Steel Casting vs. Die Casting?

- Common Misconceptions: What Myths Surround Steel Casting and Die Casting?

- Key Precautions: What Should You Avoid When Using Steel Casting or Die Casting?

- Conclusion: How to Finalize the Right Casting Process for Your Parts

I. Introduction: What Role Do Steel Casting and Die Casting Play in Manufacturing?

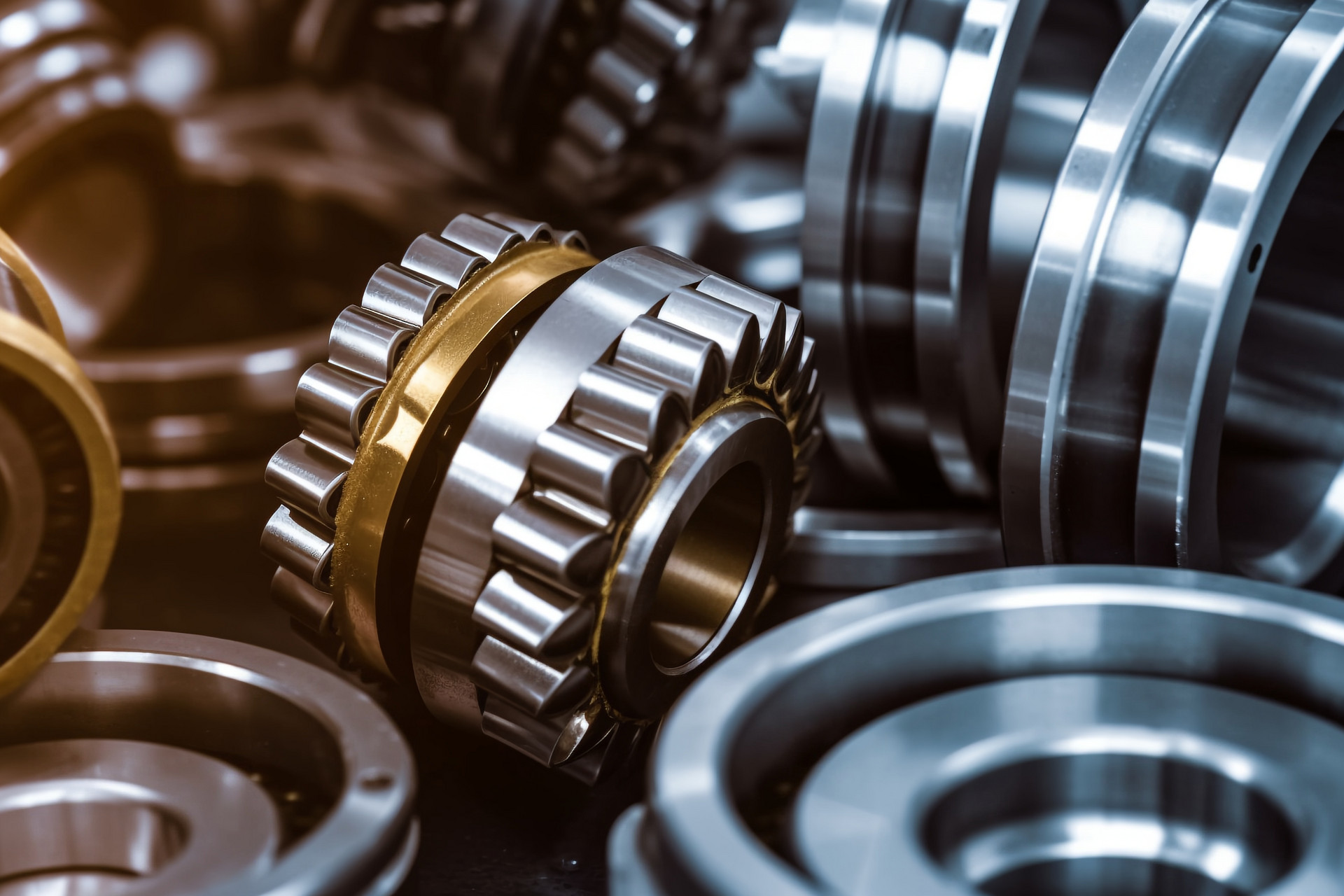

Metal casting is a key process in modern manufacturing. It works for automotive, machinery, aerospace, construction and electronics industries.

Steel casting and die casting are two popular casting methods. They differ in important ways. These differences change part performance, production cost and how fast parts are made.

Choosing the wrong process causes problems. It can delay projects, waste money or create low-quality parts.

This article explains the key traits of both processes. It uses facts, data and real examples. It helps engineers, buyers and designers make smart choices. By the end, you will know which process fits your parts best.

II. What Are the Basic Definitions and Core Principles of Steel Casting vs. Die Casting?

1. Steel Casting

Steel casting is a metal forming process. It melts steel (like carbon steel or alloy steel) into liquid. It pours the liquid steel into molds. The steel cools and hardens into the part’s shape.

- Process Principles: Steel casting relies on mold cavities. The mold’s shape decides the final part’s shape. Steel casting cools slowly. Carbon steel cools at 20-50℃ per hour. This slow cooling works for complex parts and large sizes.

- Three common types of steel casting exist: Sand casting is the most common (70% of global steel castings). Investment casting (lost-wax casting) makes precise parts. Centrifugal casting makes cylindrical parts like pipes.

2. Die Casting

Die casting is a high-pressure casting process. It uses non-ferrous metals (like aluminum, zinc or magnesium alloys). It melts these metals. It injects the molten metal into reusable metal dies at high speed.

- Die casting uses two key features: high pressure and fast filling. The pressure ranges from 10-150 MPa. The filling speed is 10-50 m/s. The metal cools quickly—seconds to minutes per part. This allows mass production.

- Die casting has three key traits: It uses reusable precision dies. These dies can last 100,000+ cycles. It makes parts with uniform structures. It works well for mass production.

III. How Do Steel Casting and Die Casting Differ in Core Aspects?

1. Which Metals Work for Steel Casting vs. Die Casting?

Steel casting works with high-melting-point metals. It uses carbon steel (A36, Q235), alloy steel (42CrMo) and stainless steel (304). These metals melt at 1,370-1,530℃. Steel casting handles these high temperatures.

Die casting works with non-ferrous metals. It uses aluminum alloy (ADC12, A380), zinc alloy (ZAMAK 3) and magnesium alloy (AZ91D). It cannot use steel. Steel’s high melting point damages die casting molds.

The American Foundry Society (AFS) reports a key fact. 95% of die cast parts use non-ferrous metals. Steel casting leads in high-strength, high-temperature uses.

2. Which Process Suits Small-Batch vs. Mass Production?

Steel casting has low single-part efficiency. Sand molds must be remade for each batch. Making one mold takes 2-5 days. Each part needs 30 minutes to 2 hours to cool. It works best for small batches (10-1,000 pieces) and many different part types.

Die casting has high efficiency for mass production. Metal dies are reusable. They make 50-500 parts per hour. One die can be used 100,000+ times. It excels at mass production (10,000+ pieces) and medium batches (1,000-10,000 pieces).

Statista data (2023) provides clear numbers. Die casting lines run at 85% efficiency in mass production. Steel casting lines run at 40-50% efficiency. Mold changes cause this lower rate.

3. Part Precision & Surface Quality: How Do Steel Casting and Die Casting Compare?

Steel casting has moderate precision. Its tolerance range is ±0.5-2 mm. Investment casting (a type of steel casting) is more precise (±0.1-0.3 mm) but costs more. Steel cast parts have rough surfaces (Ra 6.3-25 μm). They need post-processing like grinding or milling.

Die casting has high precision. Its tolerance range is ±0.1-0.5 mm for small parts. Its surfaces are smooth (Ra 1.6-6.3 μm). Most die cast parts need little post-processing. Only light deburring is often needed.

ISO 8062 (an international standard) classifies casting tolerances. Steel casting falls into IT14-IT16. Die casting falls into IT10-IT13. This means die casting meets tighter design rules.

4. Which Process Handles Complex vs. Regular Shapes?

Steel casting easily makes complex parts. It makes parts with irregular cavities, thick walls (10-100 mm) and large sizes (up to 50 tons). Sand molds can be modified flexibly. Engineers can change designs without big cost increases.

Die casting works better for regular shapes. It favors thin-walled parts (1-5 mm) and symmetrical structures. Examples include wheel hubs and phone frames. It struggles with complex internal cavities. Die casting molds have fixed parting lines. Undercuts need expensive sliding cores.

One example shows the difference. A large marine gearbox housing (2 tons, complex internal passages) uses steel casting. A smartphone middle frame (thin walls, uniform structure) uses die casting.

5. Which Process Offers Better Value for Initial Investment vs. Mass Production?

Steel casting has low initial investment:

- Sand molds cost 500-5,000USD per set.

- A small steel casting workshop needs 50,000-100,000USD in equipment.

- Its unit cost stays stable at 10-100USD per kg, no matter the batch size.

- It is cost-effective for small batches.

Die casting needs high initial investment:

- Metal dies cost 10,000-500,000USD per set.

- A die casting line costs 500,000-2,000,000USD.

- Its unit cost drops with more parts:

- 5-20USD per kg for mass production.

- 20-50USD per kg for small batches.

A cost example makes this clear.

- For 500 pieces of aluminum alloy parts (0.5 kg each): Die casting costs 25,000USD (mold + parts). Steel casting (if possible) costs 15,000USD.

- For 100,000 pieces of aluminum alloy parts (0.5 kg each): Die casting costs 80,000USD. Steel casting costs 500,000USD.

6. Which Process Delivers Toughness vs. Strength?

Steel casting makes parts with good toughness. Slow cooling creates coarse grains (100-200 μm). Carbon steel castings have tensile strength of 400-800 MPa. They have impact toughness of 20-60 J/cm². Steel cast parts can be heat-treated. Annealing, normalizing and quenching improve their performance.

Die casting makes parts with high strength. Fast cooling creates fine grains (20-50 μm). Aluminum alloy die castings have tensile strength of 200-400 MPa. Zinc alloy die castings have tensile strength of 250-350 MPa. Die cast parts have limited heat treatment options. High temperatures cause deformation or holes.

ASM International shares key advice. Steel castings work well for impact-loaded parts (like crane hooks). Die castings work well for static or low-impact parts (like brackets).

IV. What Are the Typical Application Scenarios for Steel Casting and Die Casting?

1. What Types of Industrial Components Benefit from Steel Casting?

Steel casting makes large structural parts. Examples include machine tool beds (500 kg-10 tons), crane arms and large diesel engine blocks. These parts need size, strength and flexibility. Die casting cannot provide these traits.

Steel casting fits parts needing high toughness. Gearboxes (for construction machinery), bearing seats (for industrial motors) and high-pressure valves (for oil pipelines) use steel casting. Their work environments need resistance to impact, vibration and extreme pressure.

Steel casting supports small-batch custom parts. Mining machine accessories, new engine prototypes and special equipment components use steel casting. It avoids high die costs for niche products.

2. What Types of Industrial Components Benefit from Die Casting?

Die casting dominates mass-produced auto parts. Aluminum alloy wheel hubs (1 million+ units per car model), engine brackets and zinc alloy door handles use die casting. Automakers choose it for speed, cost savings and precision.

Die casting makes electronic product shells. Magnesium alloy phone middle frames, aluminum alloy laptop casings and zinc alloy charger housings use die casting. These parts need tight tolerances and smooth surfaces.

Die casting produces precision mechanical parts. Small gears (for household appliances), aerospace electronic connectors and medical device sensors use die casting. Their small size and high volume make die casting economical.

V. How to Select Between Steel Casting and Die Casting: A Decision Framework

1. Step 1: Clarify Core Requirements – What Material, Batch Size and Precision Do You Need?

What material do you need? Choose steel casting for steel. Choose die casting for aluminum, zinc or magnesium alloys.

What is your production batch? Pick steel casting for small batches (less than 1,000 pieces). Pick die casting for mass production (more than 10,000 pieces). For medium batches (1,000-10,000 pieces), compare costs first.

What precision and surface quality do you need? Die casting works for tight tolerances (±0.1-0.5 mm) and smooth surfaces. Steel casting suits looser tolerances (±0.5-2 mm) or parts needing post-processing.

2. Step 2: Analyze Part Characteristics – What Size, Structure and Mechanical Properties Are Required?

What is the part’s size and weight? Steel casting handles large parts (over 100 kg). Die casting excels at small parts (under 10 kg).

How complex is the part’s structure? Steel casting fits irregular shapes, thick walls or complex internal cavities. Die casting suits regular, thin-walled, symmetrical parts.

What mechanical properties do you need? Steel casting provides high toughness and impact resistance. Die casting offers high strength and hardness.

3. Step 3: Evaluate Cost & Production Cycle – What Budget and Timeline Do You Have?

Can you afford high initial investment? Die casting needs expensive molds. Steel casting has low startup costs.

What is your production timeline? Die casting delivers mass-produced parts quickly. Steel casting delivers small batches faster (no long mold lead time).

4. Step 4: Reference Practical Cases – What Do Real-World Applications Show?

Case 1: Large marine engine cylinder block. Material: alloy steel. Batch: 50 pieces. Requirements: high toughness, complex structure. Process chosen: steel casting. Reason: Die casting cannot handle steel or large size. Steel casting meets toughness and complexity needs.

Case 2: Auto aluminum alloy steering knuckle. Material: A380 aluminum alloy. Batch: 100,000 pieces. Requirements: high precision, light weight. Process chosen: die casting. Reason: Die casting delivers speed, cost savings and consistent quality for mass production.

VI. What Are Common Misconceptions and Precautions for Steel Casting vs. Die Casting?

1. Common Misconceptions: What Myths Surround Steel Casting and Die Casting?

Misconception 1: Die casting is better than steel casting. Correction: No process is “better.” Each process fits different needs. Die casting fails for steel or large parts. Steel casting lags in mass production efficiency.

Misconception 2: Steel casting cannot make high-precision parts. Correction: Investment casting (a steel casting method) achieves ±0.1 mm tolerance. It works for high-precision, low-volume steel parts (like aerospace components).

Misconception 3: Die casting is always cheaper. Correction: Die casting is cheaper only in mass production. For small batches, steel casting costs 30-50% less.

2. Key Precautions: What Should You Avoid When Using Steel Casting or Die Casting?

For die casting: Maintain molds regularly. Metal dies wear after 100,000 cycles. Replace or repair them to avoid defective parts. Avoid overly thick walls (over 5 mm). Thick walls cause shrinkage holes or porosity.

For steel casting: Control sand mold quality. Poor sand quality leads to defects (sand inclusion, porosity). Test mold strength and permeability before production. Plan post-processing early. Steel cast parts need grinding or painting to meet surface requirements.

The Foundry Association of Japan (FAJ) offers key advice. 70% of casting defects come from poor process-material matching. Verify your process choice against material and design needs first.

VII. Conclusion: How to Finalize the Right Casting Process for Your Parts

Steel casting and die casting are not competitors. They are complementary processes. Each serves different manufacturing needs.

Steel casting emphasizes three key traits: flexibility, steel material adaptability and small-batch production. It serves large, complex, high-toughness parts. Die casting focuses on three key traits: efficiency, precision and mass production of non-ferrous metal parts. It delivers speed and cost savings for high-volume, regular-shaped components.

The core selection rule follows three steps: Match the process to your material. Align it with your production batch. Fit it to your part’s performance requirements. Never choose a process based on “popularity” or “cost alone.”

As AFS states in Casting Design Handbook: “The best casting process balances material, cost, quality and delivery for your specific part.”

For uncertain scenarios: Conduct small-batch trials. Test both processes (if feasible) and compare results. Consult professional casting manufacturers. Their technical expertise helps you avoid costly mistakes.

By applying the framework in this article, you will select the right forming process. You will optimize part quality, control costs and meet production deadlines. You will turn casting from a potential risk into a competitive advantage.

Saber mais sobre os nossos produtos?

Contactar agora