Is Duplex Stainless Steel the Future? The Ultimate Guide to Duplex Steel

Table of Contents

Duplex stainless steel is a kind of stainless steel with a special two-part structure. The combination of austenitic and ferritic crystals yields great strength, corrosion resistance, and versatility. It has become a very important material in many industries and is becoming the future of high-performance materials.

This guide will explain the types, properties, and applications of duplex stainless steel. It will also compare it with other stainless steels and answer common questions. We hope it will help you make better choices for your projects.

1. What Is Duplex Stainless Steel?

Before introducing duplex stainless steel, let’s briefly go over the definition of single-phase stainless steel.

Single-phase stainless steel

Single-phase stainless steel has only one main crystalline structure in its microstructure. The two most common types are austenitic stainless steel and ferritic stainless steel.

Austenitic stainless steel

- Stainless steel that has a face-centered cubic (fcc) austenite crystalline structure.

- It is the most common type of stainless steel, characterized by its soft and flexible structure. It is corrosion-resistant and easy to shape.

- Common grades include 304 and 316L.

Ferritic Stainless Steel

- Stainless steels with a body-centered cubic (bcc) ferrite crystal structure.

- It has a strong and rigid structure, is resistant to stress corrosion, and is magnetic.

- Common grades include 430 and 409.

Duplex stainless steel

Duplex stainless steel mixes the two single-phase structures above.

According to ASTM International, a leading global authority on materials standards, duplex stainless steel is defined as a stainless steel with a two-phase microstructure consisting of both austenite and ferrite, with each phase generally present in amounts of 30% to 70% by volume.

This two-in-one structure combines the best of both phases, making duplex stainless steel a perfectly balanced material for industrial applications. It has the corrosion resistance and flexibility of austenitic steel, along with the high strength of ferritic steel.

Duplex stainless steel’s exceptional performance comes from a tailored alloy composition. The core alloying elements include chromium (Cr), molybdenum (Mo), nitrogen (N), and nickel (Ni), with their typical ranges and functions outlined below:

Quick Guide: Key Alloying Elements & Functions

| Element (Symbol) | Composition Range | Main Functions |

| Chromium (Cr) | 20–30% | Primary corrosion resistance; Prevents rust and damage from chemicals; Stabilizes the ferrite phase |

| Molybdenum (Mo) | 0–5% | Enhances pitting corrosion resistance; Suitable for saltwater and acidic environments |

| Nitrogen (N) | 0.1–0.5% | Strengthens the steel; Improves Stress Corrosion Cracking (SCC) resistance; Stabilizes the austenite phase |

| Nickel (Ni) | 4–8% | Strengthens the steel; Improves Stress Corrosion Cracking (SCC) resistance; Stabilizes the austenite phase |

Manganese, copper and tungsten may also be added to further influence the specific properties of duplex stainless steel.

2. Types of Duplex Stainless Steel

Duplex stainless steel is mainly divided into four types based on its core alloying content. Distinguished by distinct gradients of chromium (Cr), molybdenum (Mo), and nitrogen (N), duplex stainless steel is mainly divided into the following four types:

| Type | Alloy Composition (Key Elements) |

| Lean Duplex (Low-Alloy) | Cr≈23%; Mo=0; N≈0.2% |

| Standard Duplex | Cr≈22%; Mo≈3%; N≈0.15% |

| Super Duplex | Cr≈25%; Mo≈4%; N≈0.3% |

| Hyper Duplex | Cr≈27%; Mo≈5%; N≈0.5% |

The difference in alloy composition directly leads to the difference in strength and corrosion resistance of duplex stainless steel. To help you better understand and compare different types, two important industry metrics are explained first: Pitting Resistance Equivalent Number (PREN) for corrosion resistance, and Yield Strength for mechanical strength.

- PREN (Pitting Resistance Equivalent Number): A metric for corrosion resistance. A higher value indicates superior corrosion resistance.

- Yield Strength: The maximum force the steel can withstand before it starts to bend or deform. A higher number indicates greater material strength (measured in MPa).

Based on the alloy composition gradient and the two indicators in ascending order, duplex stainless steel is sorted into four main types: Lean Duplex, Standard Duplex, Super Duplex, and Hyper Duplex.

2.1 Lean Duplex Stainless Steel

Lean duplex is the most cost-effective type of duplex stainless steel. It has no molybdenum added and is low alloy content, making it a budget-friendly alternative to some austenitic steels.

- Core Performance Metrics

- Yield Strength:~450 MPa

- PREN: ~24-28

- Key Traits

- Lower cost than other duplex stainless steel types

- Higher strength than 304/316L austenitic steel

- Moderate corrosion resistance

- Common Grades:

- UNS S32101 (LDX 2101)

- UNS S32304 (2304)

- Typical Applications

- Water tanks and potable water systems

- Structural beams and architectural components

- Bridges and general structural fabrications

2.2 Standard Duplex Stainless Steel

Standard duplex is the most common and widely used type of duplex stainless steel. It offers a good balance of yield strength and corrosion resistance.

- Core Performance Metrics

- Yield Strength:450-550 MPa

- PREN: ~32-35

- Key Traits

- Excellent resistance to stress corrosion cracking

- Twice the yield strength of 316L austenitic steel

- Broad service temperature range

- Common Grades:

- UNS S31803

- UNS S32205 (2205)

- Typical Applications

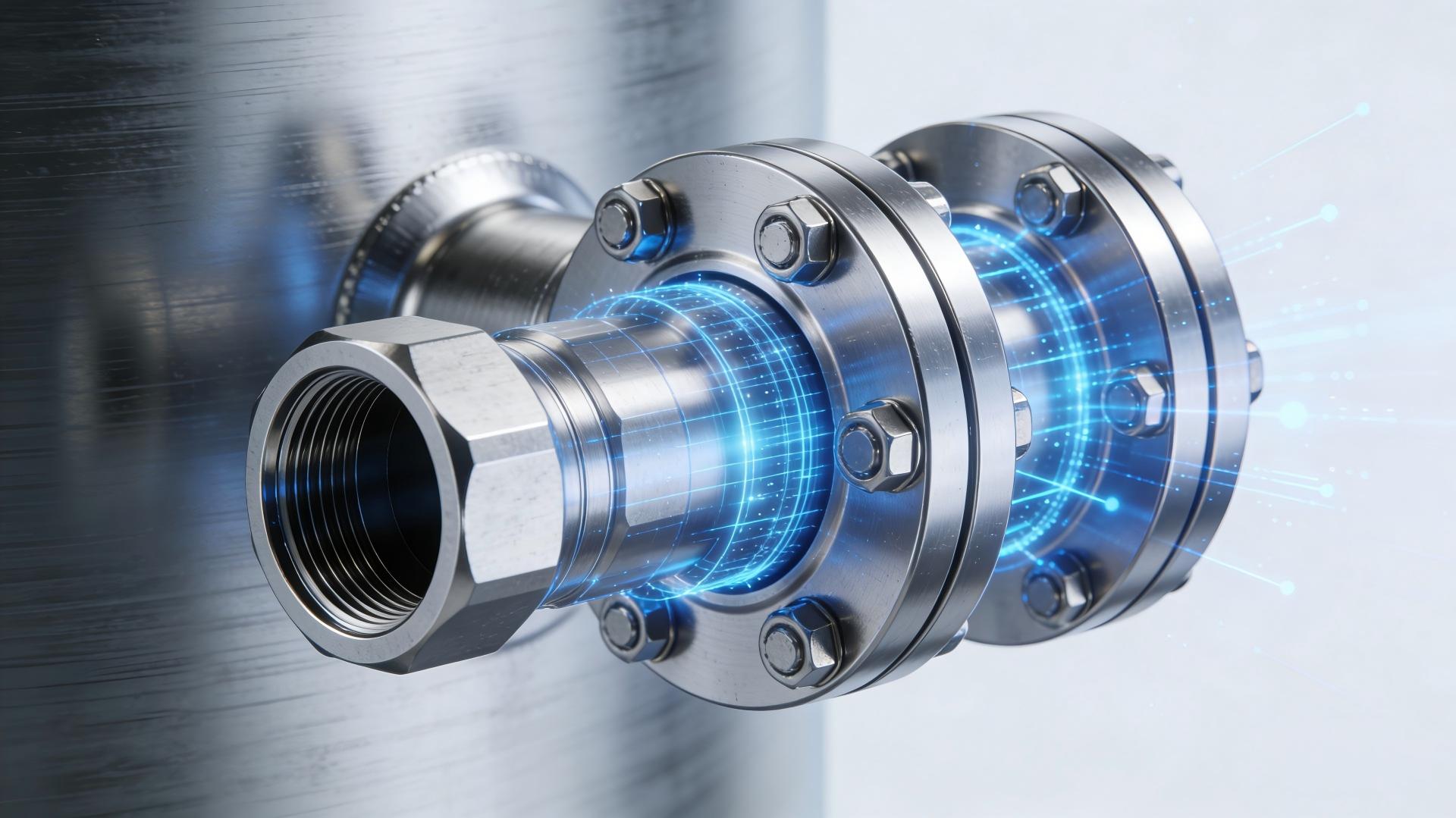

- Oil and gas piping systems

- Desalination systems

- Pressure vessels and industrial heat exchangers

- Marine structural parts

2.3 Super Duplex Stainless Steel

Super duplex has higher Cr, Mo and N content, which leads to higher strength and much better corrosion resistance than standard duplex. It can handle harsh environments, especially those with saltwater, acids, or high pressure.

- Core Performance Metrics

- Yield Strength:550-650 MPa

- PREN: ≥40

- Key Traits

- Outstanding resistance to seawater, pitting and crevice corrosion

- Higher mechanical strength than standard duplex, durable in high-pressure environments

- Optional tungsten/copper can be added to enhance acid resistance

- Common Grades:

- UNS S32750 (SAF 2507)

- UNS S32760 (Zeron 100)

- Typical Applications

- Offshore oil and gas platforms

- Seawater desalination evaporators and RO systems

- Chemical tankers that hold corrosive liquids

- Sour gas processing equipment

2.4 Hyper Duplex Stainless Steel

Hyper duplex has the highest content of Cr, Mo and N among the four types, with the most excellent performance, designed for extreme and aggressive working conditions. It is also the most expensive type.

- Core Performance Metrics

- Yield Strength: >650 MPa

- PREN: >45-50

- Key Traits

- Unmatched corrosion resistance

- Highest strength among duplex steels

- Harder to process/weld, requiring specialized techniques

- Common Grades:

- UNS S32707

- Typical Applications

- Deep-sea high-pressure pipelines

- Sour gas processing

- Ultra-harsh industrial systems

From Lean Duplex to Hyper Duplex stainless steel, the strength and corrosion resistance keep increasing, and the cost rises accordingly. You can choose the right type based on your project’s requirements and budget.

3. Core Properties of Duplex Stainless Steel

The unique dual-phase structure of duplex stainless steel blends the best of austenitic and ferritic stainless steel. Its core properties are explained below:

3.1 Mechanical Properties

- High Yield Strength: Almost twice that of austenitic stainless steel (like 304 or 316L), which means duplex stainless steel is much stronger.

- Balanced Strength & Ductility: It’s tough and flexible, won’t break or crack easily.

- Good Impact Toughness: It maintains toughness and stability in cold (-50°C) to moderately hot (up to ~300°C) conditions.

- Excellent Fatigue & SCC Resistance: Resists damage from repeated stress or pressure.

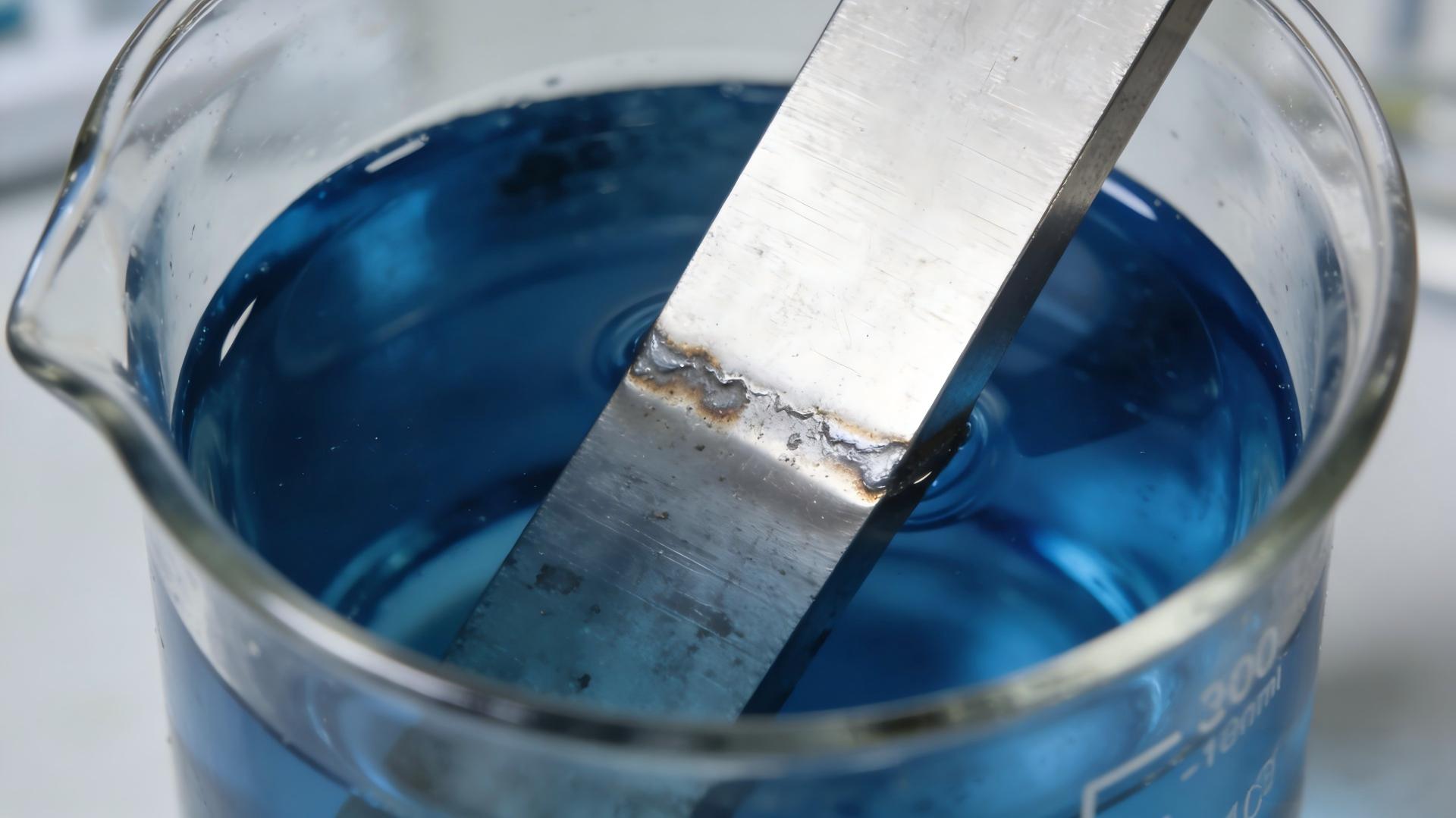

3.2 Corrosion Resistance

- General Corrosion Resistance: Resists rust and damage from water, chemicals, and salt.

- Localized & Special Corrosion Resistance: It possesses excellent resistance to pitting corrosion, crevice corrosion, and sulfide stress cracking (SSC), and can work well in wet, salty, or chemical-rich environments.

3.3 Fabrication Properties

- Weldability: Good weldability, requiring only simple temperature control.

- Formability: Better formability, easy to bend, shape, or stamp into parts.

- Machinability: High hardness, requiring proper tools to cut or machine.

4. Key Applications of Duplex Stainless Steel

Based on the high strength and corrosion resistance outlined, duplex stainless steel is widely used across industries. Here are some typical applications.

Petróleo y gas

Duplex stainless steel is a commonly used material in onshore and offshore oil and gas operations, suitable for corrosive oil well environments. Common grades and applications are as follows:

- Lean Duplex (2304, LDX 2101): Onshore pipeline systems, storage tanks for non-sour crude oil.

- Standard Duplex (2205): Shallow offshore risers, wellhead equipment, and process piping for mild sour gas.

- Super/Hyper Duplex (2507, 2707): Deep-sea subsea manifolds, sour gas processing units, and high-pressure well components.

Marine, Offshore & Water Desalination

Duplex stainless steel can address harsh saltwater environments, with its excellent resistance to pitting and crevice corrosion in seawater, it is widely applied in marine structures and water desalination systems. Typical applications are listed below.

- Standard Duplex (2205): Ship hulls, port railings, nearshore platform structural parts, desalination pre-treatment systems, RO membrane housings.

- Super/Hyper Duplex (2507, 2707): Offshore platform decks, seawater ballast systems, subsea pipelines, seawater intake pipelines, desalination evaporators, brine disposal systems.

Chemical Processing

Duplex stainless steel is a reliable material in the chemical processing industry, suitable for handling a wide range of corrosive media such as acids and alkalis.

- Standard Duplex (2205): General chemical piping, acid/alkali storage tanks, heat exchangers

- Super/Hyper Duplex (2507, 2707): High-chloride chemical reactors, pulp & paper liquor tanks, chemical tanker hulls

Structural & Architectural Engineering

Duplex stainless steel is a high-performance material for structural and architectural projects, valued for its excellent strength-to-weight ratio and resistance to mild corrosion. Common grades and their targeted applications are as follows:

- Lean Duplex (2304, LDX 2101): Bridges, architectural facades, structural beams, potable water distribution pipelines, general water storage tanks

- Standard Duplex (2205): Industrial pressure vessels, food processing equipment

5. Duplex Stainless Steel vs. Other Stainless Steel

We have explained the core properties and applications of duplex stainless steel in detail. To highlight the difference between duplex stainless steel and other stainless steels, a side-by-side comparison table is summarized below.

Comparison of Duplex Stainless Steel vs. Other Stainless Steel

| Key Comparison Metric | Austenitic Stainless Steel | Ferritic Stainless Steel | Duplex Stainless Steel |

| Microstructure | Face-Centered Cubic (FCC) austenite structure | Body-Centered Cubic (BCC) ferrite structure | Dual-phase (austenite + ferrite) |

| Yield Strength | Low (~205 MPa) | Moderate (~275 MPa) | High (~450 MPa) |

| Hardness | Low to moderate hardness, excellent toughness | Moderate hardness, poor low-temperature toughness | Excellent hardness, moderate toughness |

| PREN Value | 18–26 | 20–30 | 24–50+ |

| Corrosion resistance | Good (for daily use) | General, sensitive to chloride corrosion | Excellent (resists seawater, brine and chemical erosion) |

| Magnetic Behavior | Non-magnetic | Fully magnetic | Slightly magnetic |

| Workability | Easy to form and weld, good machinability | Kitchenware, architecture, and daily-use products | Poor (hard and strong), requires specialized welding/machining |

| Cost | Moderate | Low | High |

| Core Advantage | Excellent ductility, weldability and versatility for daily use | Cost-effective with basic corrosion resistance | Balanced high strength and corrosion resistance for harsh environments |

| Typical Grade | 304, 316 | 430, 409 | 2205, 2507 |

| Key Application | Kitchenware, architecture, daily-use products | Automotive trim, exhaust systems | Oil and gas, marine, water treatment |

To sum up, the three types of stainless steel have distinct advantages and applicable scenarios:

Austenitic stainless steel (304, 316) is the most versatile and is the first choice for daily use. It has great toughness and is easy to process, making it suitable for most civil and general industrial applications requiring corrosion-resistant materials.

Ferritic stainless steel (430, 409) has the advantage of low cost, which can meet basic corrosion resistance needs. It is suitable for budget-sensitive and low-demand situations. But be aware that it is not suitable for low-temperature environments due to its poor low-temperature toughness.

Duplex stainless steel (2205, 2507) shows significant advantages in applications that require both high strength and corrosion resistance. Its yield strength is more than twice that of 304 stainless steel, and it possesses excellent resistance to chloride stress corrosion. These properties lead to its unique role in harsh environments. However, its processing difficulty and cost are higher, which limit its use in less demanding applications.

6. How to Choose the Right Stainless Steel

To choose the right stainless steel for your project, you should match the material to the specific project requirements. We have listed four reminders that you need to think about before making a decision:

Evaluate the service environment & corrosion requirements

The service environment should be confirmed first. The environment determines the corrosion resistance needs—including the corrosive media, concentration, and service time in the specific setting.

- For mild corrosion environments (indoor air, fresh water, non-corrosive industrial gas), materials with PREN≥18 are sufficient. Suitable options include Austenitic steel Grade 304, Ferritic Stainless Steel Grade 430, and Lean Duplex Stainless Steel Grade 2304.

- For moderate corrosion environments (coastal air, dilute acids/alkalis, low-concentration salt spray), a PREN ≥ 24 material is required. Materials available include Austenitic Stainless Steel Grade 316 (with molybdenum) and Duplex Stainless Steel Grade 2205 (duplex 2205).

- For severe corrosion environments (saltwater, sour gas, high-chloride chemicals), the PREN ≥ 40 material is a must. Only Super Duplex Stainless Steel Grade 2507 (duplex 2507) or Hyper Duplex Stainless Steel Grade 2707 (duplex 2707) can handle the long-term stable operation in these harsh environments.

Match the performance needs based on application scenarios

Different application scenarios have specific requirements for material strength, toughness, magnetic properties, and temperature.

- For high strength requirements, duplex stainless steel such as 2507 or 2707 are ideal; by contrast, you can choose a single-phase stainless steel 304, 430.

- For scenarios requiring non-magnetic properties (precision instruments, medical equipment), choose 304 or 316; If magnetic properties are not required, choose ferritic or duplex stainless steel instead.

- In the low temperature environment (-50 ° C to 0 ° C), avoid ferritic stainless steel, which is prone to brittle fracture at low temperatures; in the ultra-high-temperature environment (>300°C), more heat-resistant materials like 316 or special heat-resistant duplex steel is required.

Clarify Budget Constraints

Clarifying your budget helps avoid over-engineering or compromised performance due to cost constraints:

- Low budget: The ferritic steel 430, 409 or austenitic steel 304 are more cost-efficient choices for industrial applications with basic corrosion resistance and structural needs.

- Medium budget: Materials with better corrosion resistance or strength, such as austenitic stainless steel 316 or lean duplex stainless steel 2304 can be used in a wider range of applications.

- High budget: Designed for high-risk industrial environments, duplex stainless steel is a higher budget option.

Consider Fabrication Feasibility

A mismatch in machining feasibility can increase machining costs and affect project progress. You should choose the right material according to your machining capability.

- For simple or general fabrication: Austenitic steels 304, 316 and ferritic steels 430 as well as duplex steels 2304, 2205 are all available options. They only require ordinary welding, bending, or stamping processes.

- For Professional fabrication: Hard, strong materials like Super Duplex 2507 or Ultra-High Duplex 2707 require specialized tools and techniques to ensure processing quality.

7. Conclusion

With the advancement of the global industry, the demand for materials is more focused on the combination of durability, efficiency, and sustainability.

Duplex stainless steel stands out for its excellent balance of strength and corrosion resistance. It supports sustainable development: Its high strength makes materials thinner and reduces resource consumption. Its long service life reduces maintenance costs and waste. It offers reliable and cost-effective solutions in harsh environments and its range of applications keeps expanding.

For industrial projects needing strength, corrosion resistance, and sustainability, it’s not just a choice—it’s the future.

This guide comprehensively covers core knowledge about duplex stainless steel, including its definition, composition, types, properties, and applications. We hope this blog assists your material selection process. For further inquiries, please feel free to contact SUMEC METAL.

Más información sobre nuestros productos

Contacto