Steel Products by Process

Why Choose SUMEC Metal

Delivering Consistent Quality, Competitive Pricing, and Dedicated Service.

Semi-finished Products

SlabSlab is primary semi-finished steel product with a large, flat rectangular shape, designed as the key feedstock for rolling into flat steel products.

Slab is primary semi-finished steel product with a large, flat rectangular shape, designed as the key feedstock for rolling into flat steel products (e.g., hot-rolled coils, heavy plates, cold-rolled sheets). Distinguished from other semi-finished steels (e.g., blooms for sections, billets for bars/wire rods), slabs have characteristic dimensions: typically 150–300 mm thick, 1,000–3,200 mm wide, and 2–12 m long (varies by mill capacity). Its flat geometry enables efficient conversion into wide, thin steel products critical for construction, automotive, and industrial sectors.

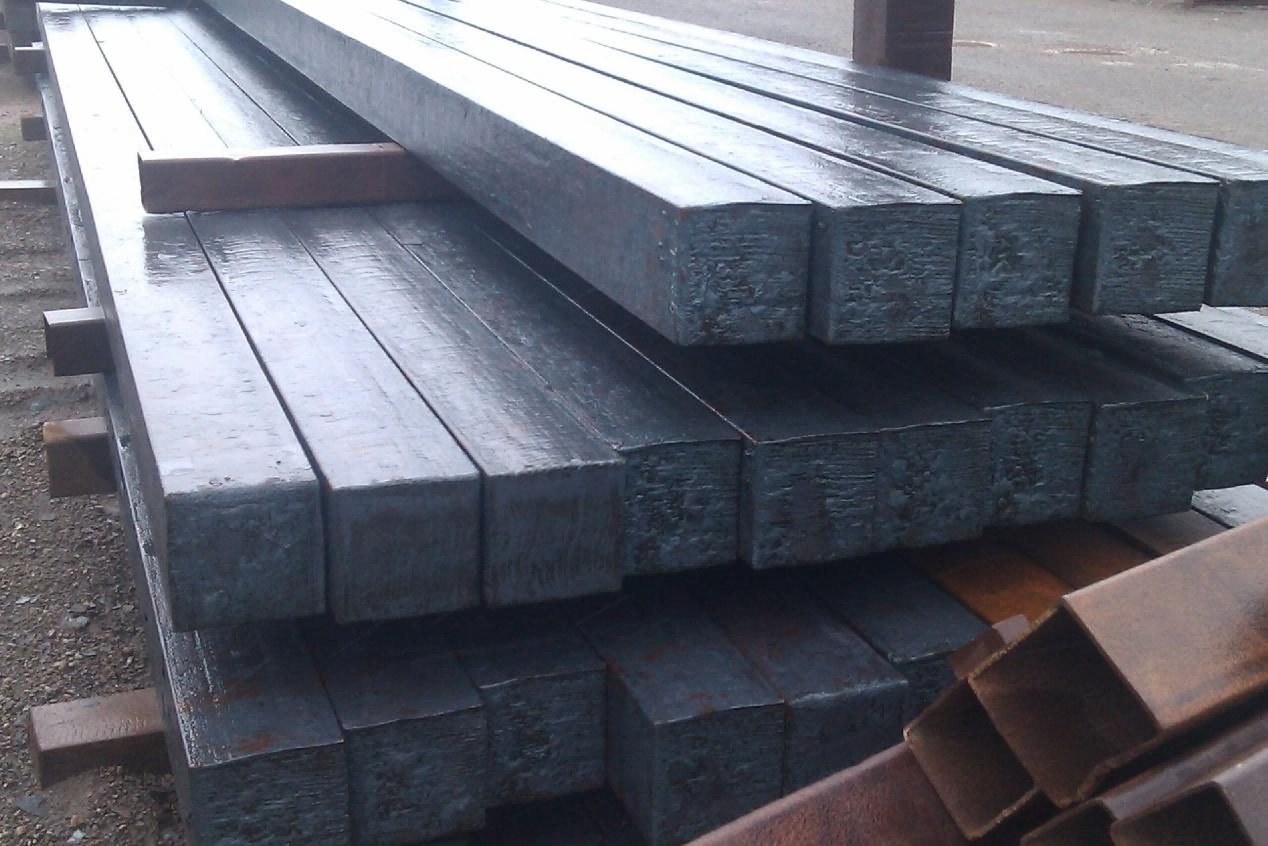

BilletBillet is key semi-finished steel product with a small, uniform cross-section.

Billet is key semi-finished steel product with a small, uniform cross-section—typically square (100–200 mm side length) or round (100–200 mm diameter)—and a length of 3–12 meters. Unlike slabs (flat, for flat steel) or blooms (larger cross-sections, for structural sections), billets are specifically designed as feedstock for rolling into long steel products (e.g., bars, wire rods, seamless tubes) or for forging into precision mechanical parts. Its compact, regular cross-section enables efficient deformation into narrow, elongated finished goods critical for construction, automotive, and machinery industries.

Bloom/ CC roundsBlooms are large semi-finished steel products with a rectangular or square cross-section.

Blooms are large semi-finished steel products with a rectangular or square cross-section, typically used as feedstock for further hot rolling into intermediate or finished steel products. They are a key intermediate in the steel manufacturing chain, bridging primary steelmaking (e.g., BOF, EAF) and downstream processing.

Pig IronPig iron is a primary iron-carbon alloy produced by smelting iron ore in a blast furnace.

Pig iron is a primary iron-carbon alloy produced by smelting iron ore in a blast furnace. It serves as the foundational raw material for steelmaking and cast iron production. The name originates from historical casting practices, where molten iron was poured into sand molds arranged in a “sow-and-pig” pattern (a large central mold “sow” feeding smaller “pig” molds), forming ingots resembling small pigs.

Hot-Rolled Steel Series

Hot-Rolled Steel CoilsHot-rolled steel coils are a type of steel produced through a high-temperature rolling process.

Hot-rolled steel coils are a type of steel produced through a high-temperature rolling process. During this process, the steel billet can change properties, size, and shape to create steel products according to specific requirements.

Hot-rolled steel coils are basic carbon steel products commonly used for applications in which dimensional tolerances and surface finish quality are not critical, such as Agriculture Equipment, Automobile Accessories, Automotive Frames, Construction, Pipe and Tubular Products, Railway Tracks, Transportation Infrastructure, etc.

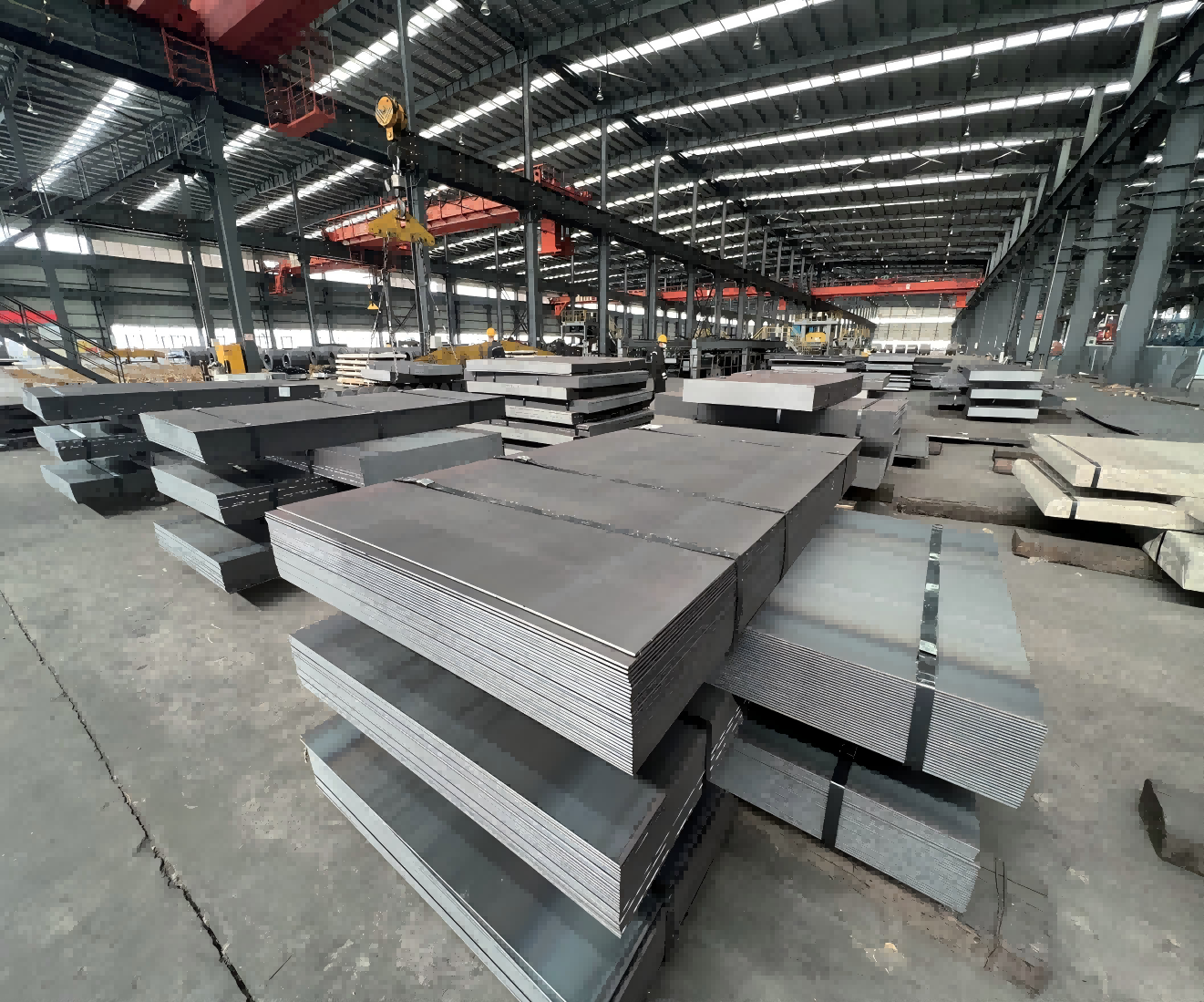

Hot-Rolled Steel Sheets and PlatesHot-Rolled Steel Sheets and Plates offer good weldability, formability and value which makes them suited across structural, manufacturing and fabrication applications.

Hot-rolled steel plates offer good weldability, formability, and value, which makes them suited across structural, manufacturing, and fabrication applications. Their combination of strength and cost-effectiveness drives widespread adoption in almost every heavy industry sector requiring durable steel components.

Due to their strength, durability, and cost-effectiveness, hot-rolled steel Sheets and Plates are mainly used in construction engineering, mechanical manufacturing, container manufacturing, shipbuilding, bridge construction, etc. They can also be used to manufacture pressure vessels, furnace shells, furnace plates, and automotive static steel plates etc.

Hot-Rolled Checkered PlatesHot-rolled checkered/patterned plate is a hot rolled steel coil with diamond (teardrop) pattern on the surface.

Hot-rolled checkered/patterned plate is a hot-rolled steel coil with diamond (teardrop) pattern on the surface. Because the pattern is diamond-shaped, the surface of the plate is rough and can be used to make general products such as floors, decks, stairs, elevator floors, etc. It is widely used in transportation, construction, decoration, equipment, flooring, machinery, shipbuilding, and other fields.

Hot-Rolled Round BarsHot-rolled steel round bars are usually used in machinery manufacturing industry, such as machine bed, bearing seat, transmission shaft, etc..

Hot-rolled steel round bars are usually used in the machinery manufacturing industry, such as machine beds, bearing seats, transmission shafts, ferrules, balls, pin roller, gear connecting rods, mine grinding balls, Caterpillar track joint shaft, high-pressure boiler pipe, bearings, gears, tracks, etc.

Cold-Rolled Steel Series

Cold Rolled Steel Coils/SheetsCold-rolled steel is the base material for galvanized steel coil and pre-painted galvanized steel coil.

Cold-Rolled Steel Coil is low-carbon hot-rolled steel that has been cleaned of oxide scale and then undergoes a specific series of processes: First, it is rolled to a thickness slightly over the desired value, then heated to controlled temperatures, and finally rolled to the desired thickness. Cold-rolled steel coils are used where thickness tolerances and surface conditions are important for light-gauge applications.

Cold-rolled steel is the base material for galvanized steel coil and pre-painted galvanized steel coil. It is widely used in the light industry for making tanks, furniture, pipes, refrigerators, washers, freezer plates, air conditioners, water heaters, hardware, automotive fittings, etc.

Coated/Plated Steel Series

Zn-AL-Mg Coated Steel Coils/SheetsHot-Dipped Zn-AL-Mg Coated Steel Coils is an alloy coating product by adding appropriate Al, Mg, and other alloy elements to the hot-dipping process on the basis of traditional zinc coating coils.

Hot-Dipped Zn-AL-Mg Coated Steel Coils is an alloy coating product by adding appropriate Al, Mg, and other alloy elements to the hot-dipping process on the basis of traditional hot-dipped zinc coating coils. Its atmospheric corrosion resistance is more than three times that of normal hot-dipped zinc-coated products (GI) with the same coating weight, and the corrosion resistance of the cutting area is particularly obvious.

Galvanized Steel Coils/SheetsGalvanized Steel Coils/Sheets (in coil or sheet form) have a zinc coating via galvanizing.

Galvalume/Aluzinc Steel Coils/SheetsHot-Dipped Galvalume Steel Coil (GL) is produced based on a cold-rolled steel coil with a coating of zinc and aluminum.

Hot-Dipped Galvalume Steel Coil (GL) is produced based on a cold-rolled steel coil with a coating of zinc and aluminum. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, which makes it gain excellent corrosion and heat resistance performance. It can be used in below situations.

1 Construction: roofs, walls, garages, soundproof walls, pipes, and modular houses, etc.

2 Automobiles: mufflers, exhaust pipes, wiper attachments, fuel tanks, truck boxes, etc.

3 Home appliances: refrigerator back panels, gas stoves, air conditioners, electronic microwave ovens, CRT explosion-proof belts, LED back lights, electrical cabinets, etc. Agricultural uses: pig houses, chicken houses, granaries, greenhouse pipes, etc.

4 Others: thermal insulation covers, dryers, water heaters, etc.

Prepainted Galvanized/Aluzinc Steel CoilsWith GI/GL as base metal, after pre-treatment (degrease and chemical treatment) and liquid dope with several layers of paint, such steel coil is called pre-painted galvanized/aluzinc steel(PPGI/PPGL).

With GI/GL as base metal, after pre-treatment (degrease and chemical treatment) and liquid dope with several layers of paint, such steel coil is called pre-painted galvanized/aluzinc steel(PPGI/PPGL). PPGI is capable of decoration, molding, and corrosion resistance. PPGL displays superior workability, durability, and weather resistance. It is mainly used in roofs, roof structures, surface sheets of balconies, frames of windows, doors, the door of the garage, roller shutter door, booth, Persian blinds, cabana, refrigerated wagon, door, frame of door, light steel structure of the house, sliding door, folding screen, ceiling, internal decoration of elevator, etc.

Why Trust SUMEC Metal

One of China's Largest & Most Trusted Steel Exporters

300M+

Tons Annual Volume

120+

Countries & Regions Served

5,000+

Global Clients

Your Strategic Advantage in Steel

Go Beyond Sourcing. Gain a Competitive Edge.

01.

Tons Annual Volume

02.

Achieve Optimal Sourcing Value

03.

Enhance Your Financial Flexibility

04.

Streamline Your Procurement Process

.png)