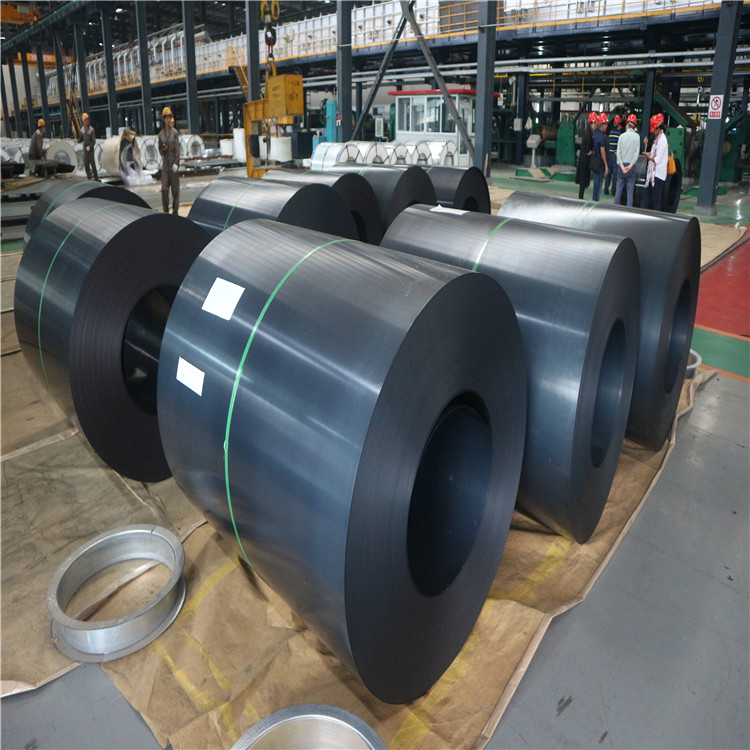

Cold Rolled Steel Coils/Sheets

Cold-Rolled Steel Coil is low-carbon hot-rolled steel that has been cleaned of oxide scale and then undergoes a specific series of processes: First, it is rolled to a thickness slightly over the desired value, then heated to controlled temperatures, and finally rolled to the desired thickness. Cold-rolled steel coils are used where thickness tolerances and surface conditions are important for light-gauge applications.

Cold-rolled steel is the base material for galvanized steel coil and pre-painted galvanized steel coil. It is widely used in the light industry for making tanks, furniture, pipes, refrigerators, washers, freezer plates, air conditioners, water heaters, hardware, automotive fittings, etc.

Why Choose SUMEC Metal for Cold Rolled Steel Coils/Sheets

300M+

5,000+

Cold Rolled Steel Coils/Sheets

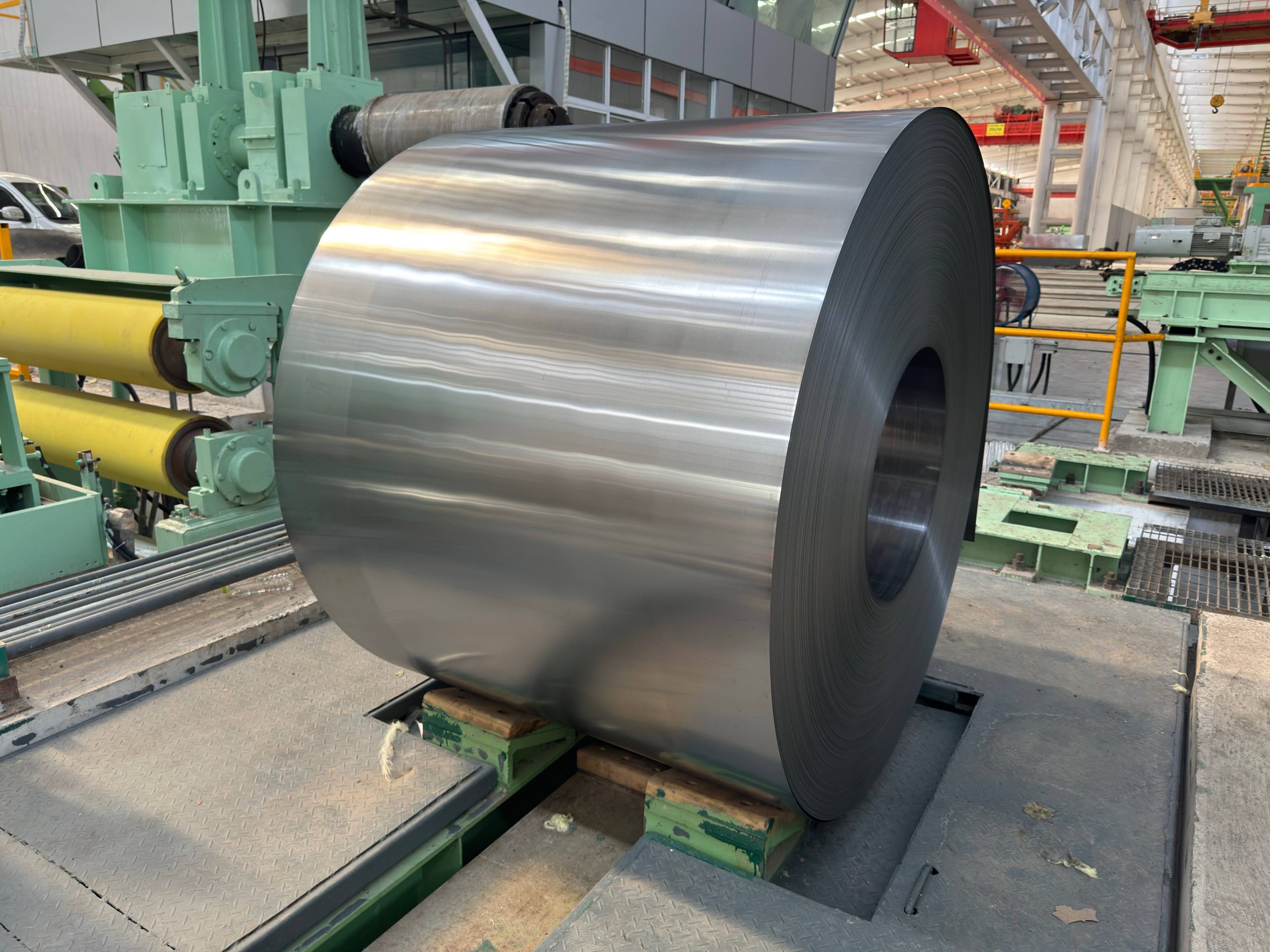

Cold-rolled Full Hard Steel CoilA Cold-rolled Full Hard (CRFH) steel coil is a high-strength, high-hardness steel product produced by cold reducing hot-rolled, pickled steel without any subsequent annealing or heat treatment.

A Cold-rolled Full Hard (CRFH) steel coil is a high-strength, high-hardness steel product produced by cold reducing hot-rolled, pickled steel without any subsequent annealing or heat treatment. Cold-rolled Full Hard (CRFH) steel coil is primarily used in scenarios needing high strength and no subsequent softening; it is characterized by high strength, high hardness, made by cold reducing hot-rolled pickled steel without subsequent annealing. Cold-rolled Full Hard (CRFH) steel coil is often used in industrial applications like automotive, home appliance, and hardware industries, where materials need stable mechanical properties during cold processing.

thickness:0.1mm-2.5mm

width 600-1250mm

grade Q195/SPHC/SAE1006

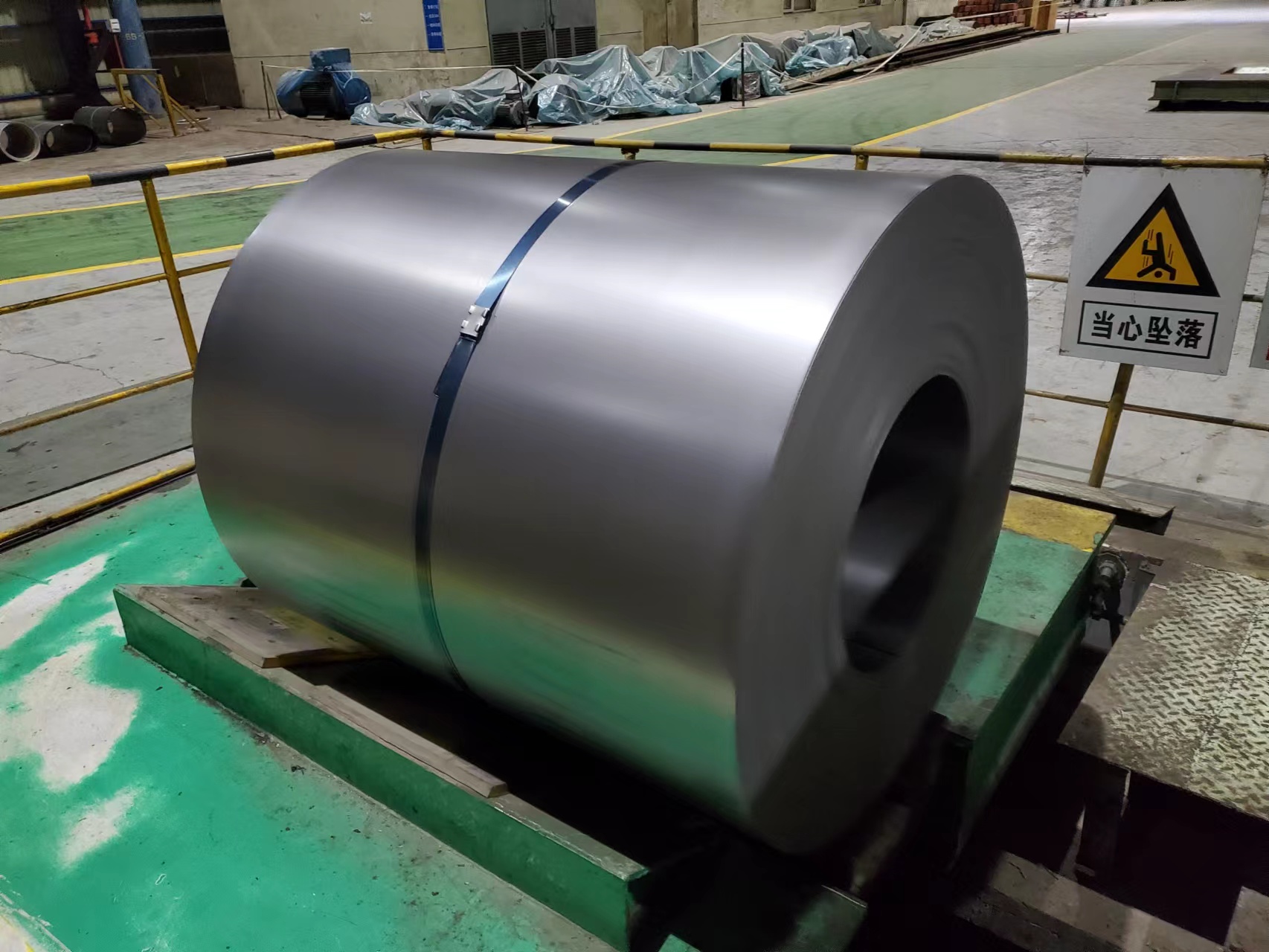

Cold-rolled Annealled Steel CoilA Cold-rolled Annealed Steel Coil (CRA) is a balanced-strength, good-formability steel product produced by cold reducing hot-rolled, pickled steel followed by subsequent recrystallization annealing heat treatment to eliminate work hardening.

A Cold-rolled Annealed Steel Coil (CRA) is a balanced-strength, good-formability steel product produced by cold reducing hot-rolled, pickled steel followed by subsequent recrystallization annealing heat treatment to eliminate work hardening. Cold-rolled Annealed Steel Coil (CRA) is primarily used in scenarios needing balanced strength and good formability; it is characterized by balanced strength, good formability, made by cold reducing hot-rolled pickled steel, then recrystallization annealing to eliminate work hardening. Cold-rolled Annealed Steel Coil (CRA) is often used in industrial applications like automotive interior parts and home appliance casings, where materials need easy forming with moderate strength.

thickness 0.2-3.0

width 600-1500

Cold-rolled Black Annealled Steel CoilA Cold-rolled Black Annealed Steel Coil (CRBA) is a cost-effective, moderately formable steel product produced by cold reducing hot-rolled, pickled steel and annealing it in a non-full protective atmosphere, retaining a thin black oxide film on its surface.

A Cold-rolled Black Annealed Steel Coil (CRBA) is a cost-effective, moderately formable steel product produced by cold reducing hot-rolled, pickled steel and annealing it in a non-full protective atmosphere, retaining a thin black oxide film on its surface. Cold-rolled Black Annealed Steel Coil (CRBA) is primarily used in scenarios needing cost control and moderate formability; it is characterized by cost-effectiveness, moderate formability, made by cold reducing hot-rolled pickled steel and annealing in a non-full protective atmosphere (retaining thin black oxide film). Cold-rolled Black Annealed Steel Coil (CRBA) is often used in industrial applications like hardware fittings and simple structural parts, where materials need low cost with basic forming performance.

thickness 0.3-1.35

width 900-1250mm

Capabilities

Grades

Application Cases